Rafnar Constructed RIBS Using MAFI equipment

Marine Airflow's Equipment On Polar Expedition RIBS

Rafnar UK has recently supplied two RIBs (rigid inflatable boats) to a client who does polar expeditions. Marine Air Flow has provided the engine room ventilation systems for both these vessels.

The boats will transfer guests and crew to and from a larger mother ship in addition to ferrying supplies when required. These boats could be working in fairly extreme conditions on occasion and it was essential that they be able to weather what might be harsh operating environments.

Acting as pathfinders for the mother ship, the vessels have been painted in vibrant colors not just to ensure high visibility, but so they can lead their mother ship as port and starboard indicators. I'm sure you will agree they will be hard to miss and its an ingenious idea!

Rafnar UK has recently supplied two RIBs (rigid inflatable boats) to a client who does polar expeditions. Marine Air Flow has provided the engine room ventilation systems for both these vessels.

The boats will transfer guests and crew to and from a larger mother ship in addition to ferrying supplies when required. These boats could be working in fairly extreme conditions on occasion and it was essential that they be able to weather what might be harsh operating environments. Acting as pathfinders for the mother ship, the vessels have been painted in vibrant colors not just to ensure high visibility, but so they can lead their mother ship as port and starboard indicators.

I'm sure you will agree they will be hard to miss and its an ingenious idea!

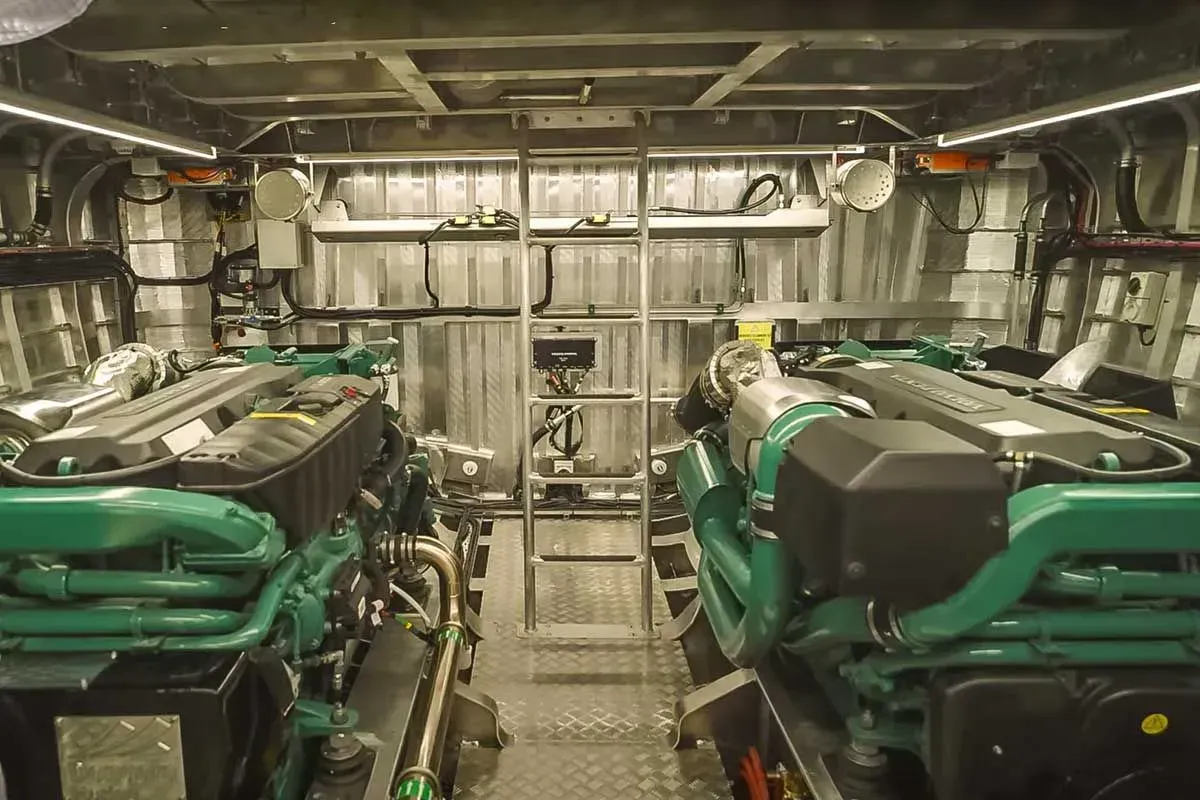

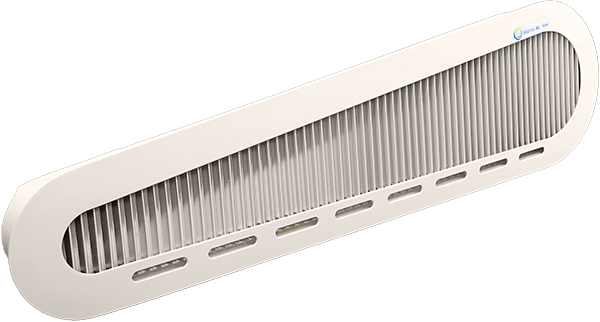

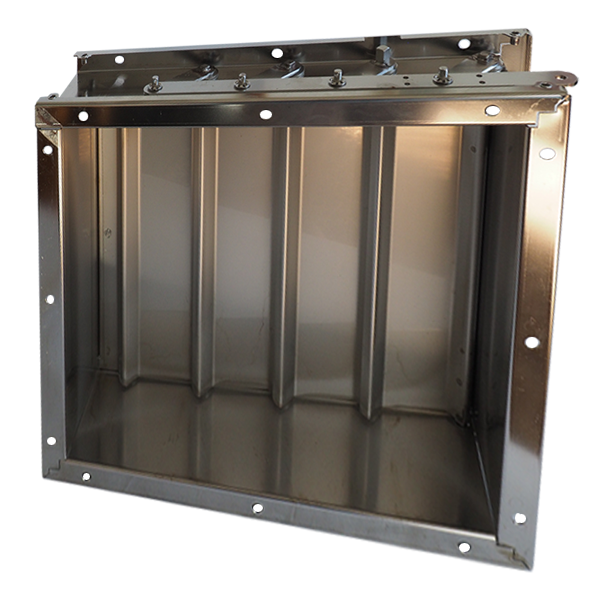

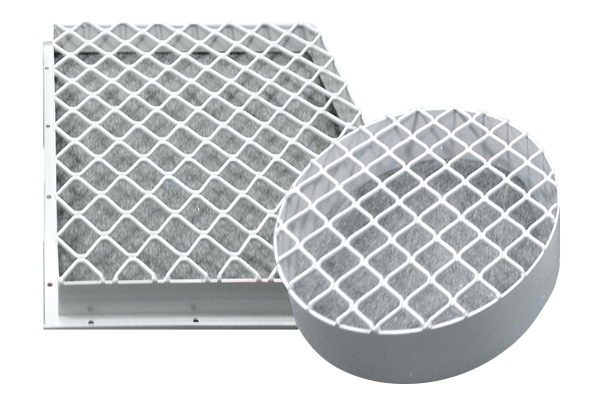

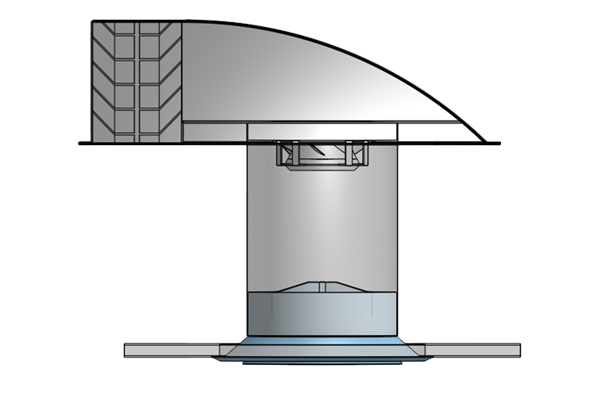

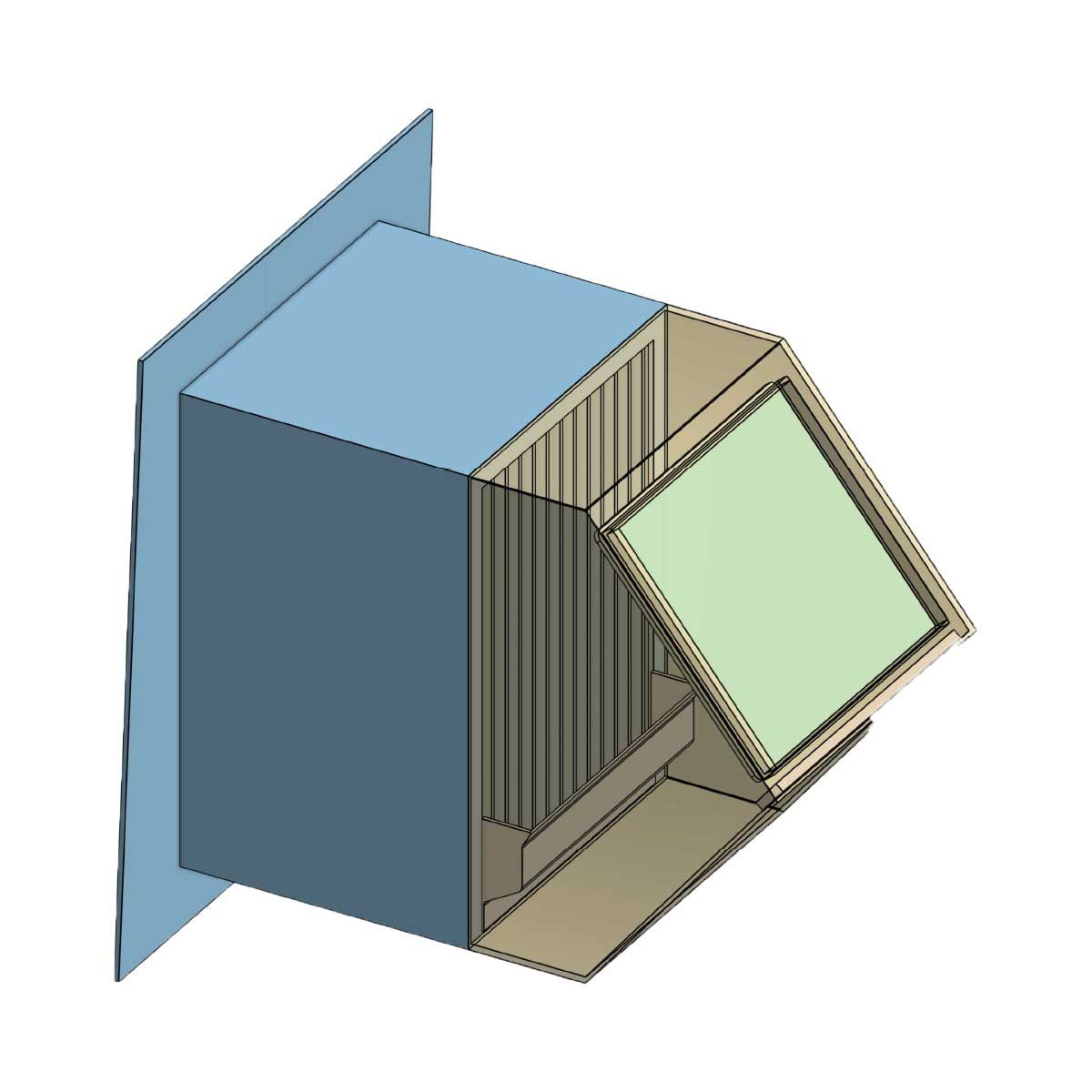

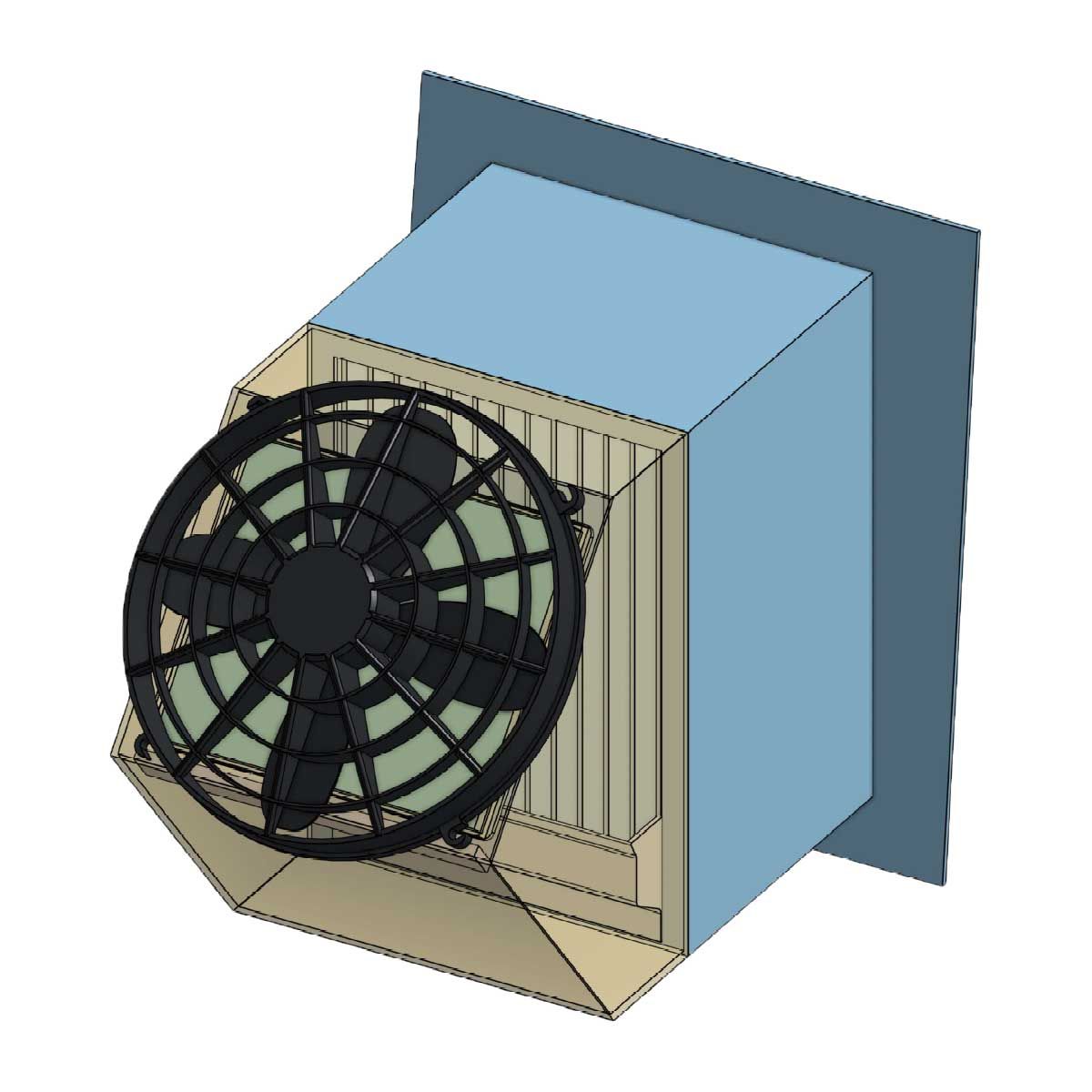

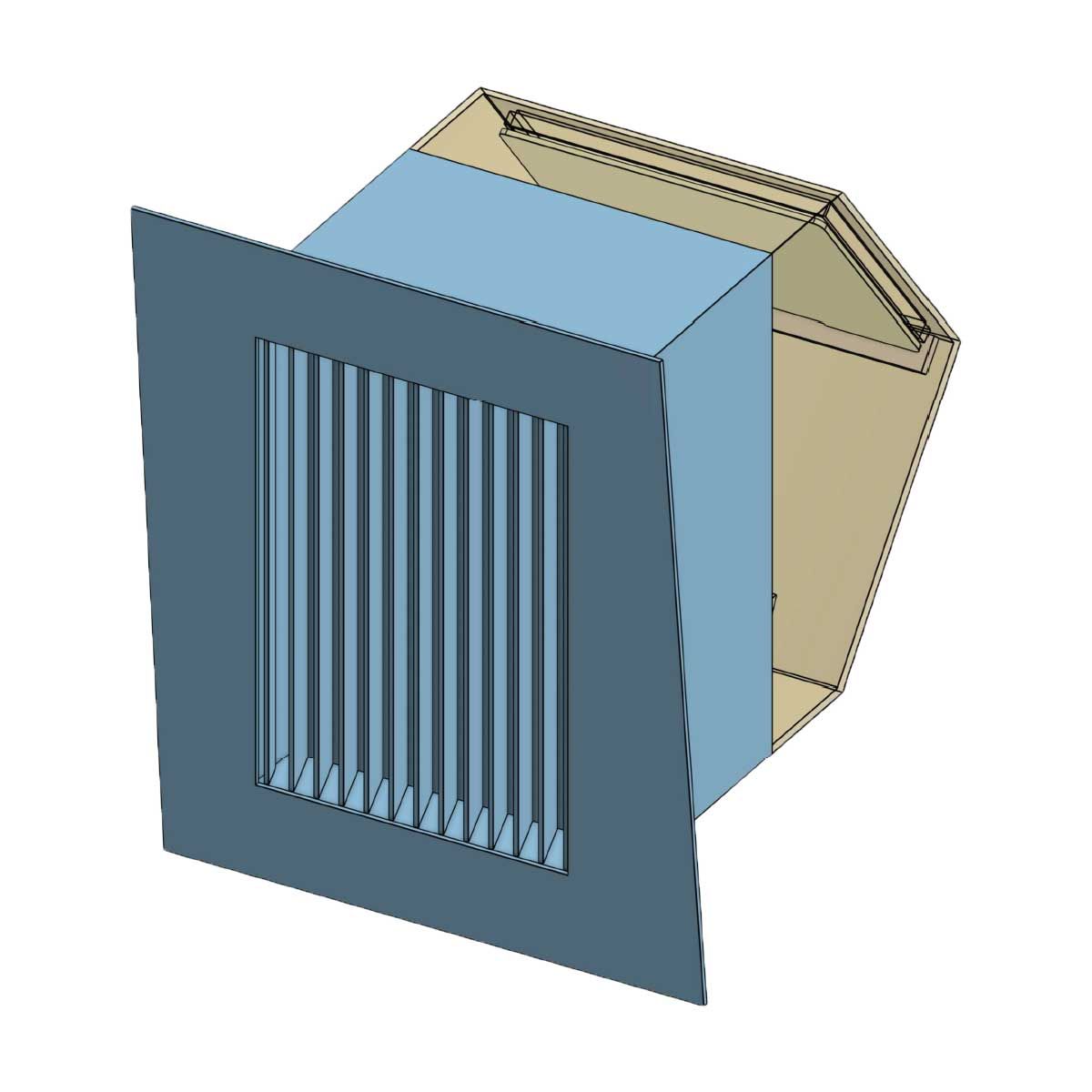

These custom designed air intake grilles are mounted with our DC compact fans which not only help protect the engine room from moisture and salt spray, but also assists with cooling to help maintain correct operating temperatures for the engines.

Operating in any harsh environment brings its own challenges, however it is also a situation where you never want to experience plant failure. Enabling the motors to run at a preferred temperature and without the risk of damage from the possible conditions is key to staying safe in these situations.

You can see from the face of the grille that the flange was designed to align with the design of the vessel, but still allow the vanes to run perfectly vertical as they need to.

Congratulations to Rafnar Maritime for another quality build. Their reputation as a vessel manufacturer is second to none and Marine Air Flow is proud to have such a close association with such an innovative and reputable company. We visited their factory in Iceland in 2017 and Brad came away extremely impressed with not just their capabilities but they day to day processes.

If you are not aware, Össur Kristinsson came from the world of prosthetics before venturing into marine hull design. Rafnar hulls are known for their "anti-slamming" technology which means a much better ride than a traditional hull. If you are considering purchasing a vessel specifically designed for rough seas, please consider Rafnar.

Check our some other Completed Projects