SCR And Marine Engine Room Ventilation

Marine Selective Catalytic Reduction (SCR) Systems: Cleaner Solutions For Maritime Applications

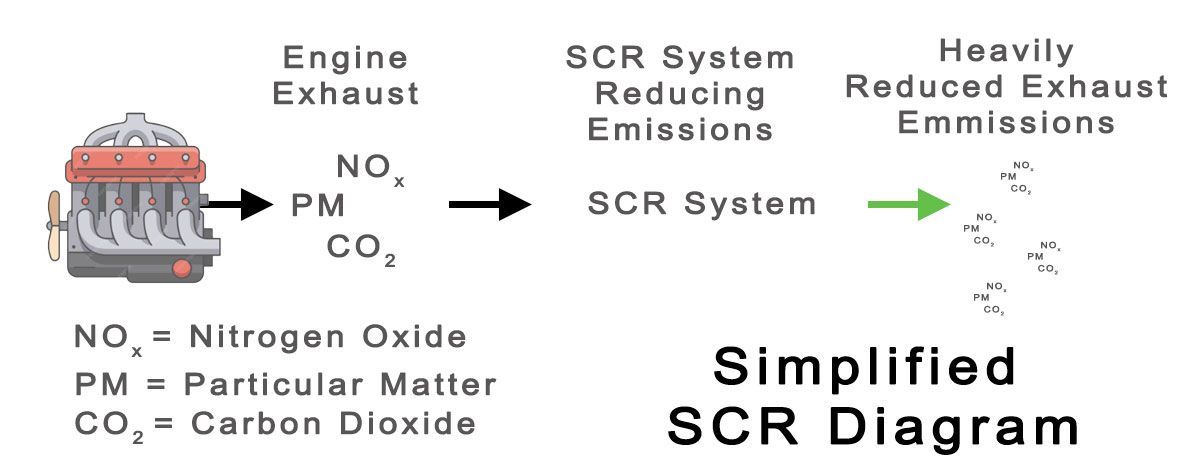

The marine industry is under increasing pressure to cut harmful emissions and operate more sustainably. One of the most effective ways to achieve this is through Selective Catalytic Reduction (SCR) systems, a proven technology that reduces nitrogen oxides (NOx) in marine engines.

At Marine Air Flow International (MAFI), we work alongside shipbuilders, operators, and defence clients to ensure that our ventilation systems are designed for efficiency, compliance, long-term reliability and to work alongside SCR units.

What is a Marine SCR System?

A Selective Catalytic Reduction (SCR) system is an after-treatment solution designed to reduce NOx emissions. It works by injecting a urea-based solution, often called Diesel Exhaust Fluid (DEF) or AdBlue, into the exhaust gases. As these gases pass through a catalyst, the NOx reacts with the fluid and is broken down into nitrogen and water vapour.

This process can reduce NOx emissions by up to 90%, helping vessels meet various emission standards and supporting a cleaner marine environment.

Why Are SCR Systems Vital in Marine Operations?

- Regulatory Compliance

With IMO Tier III and other regional requirements in place, SCR technology ensures vessels remain compliant in Emission Control Areas (ECAs). - Environmental Responsibility

Reduced NOx means less smog, acid rain, and air pollution—protecting both marine and coastal ecosystems. - Performance and Flexibility

SCR systems can be adapted for a wide range of marine engines, including high-performance patrol boats, commercial ferries, and defence vessels. - Future-Proofing Fleets

As emission standards continue to tighten, SCR provides a robust pathway for long-term compliance.

How SCR Systems Work

The process is straightforward yet highly effective:

- Injection: Urea solution is sprayed into the exhaust stream.

- Catalysis: Exhaust gases pass through a catalyst where NOx is converted.

- Conversion: The reaction turns harmful NOx into nitrogen and water.

- Clean Output: The result is significantly cleaner emissions leaving the stack.

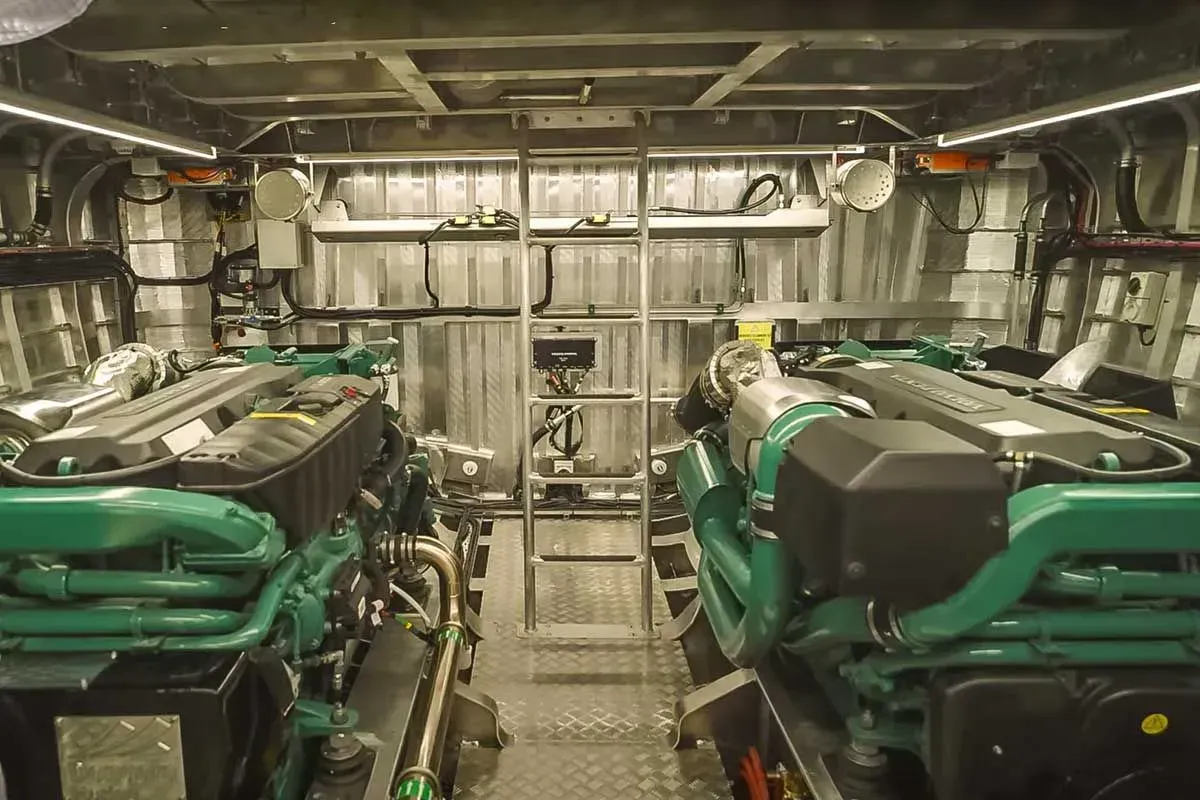

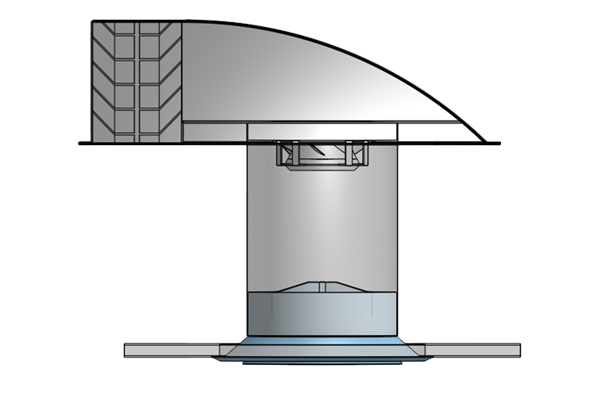

How SCR Systems Can Affect Your Engine Room Temperatures

By design SCR Systems can and do run very warm. This can have a decent impact on your engine room temperatures, increasing them toward undesirable levels of heat.

If your SCR system is not encapsulated and/or insulated you can end up with a lot more heat in your engine room space. The knock on effect of this is that you can require a lot more air induction to counteract this. However if the SCR location is taken into consideration before your ventilation system is designed we can usually account for the extra heat quite effectively.

MAFI’s Role in Supporting SCR Technology

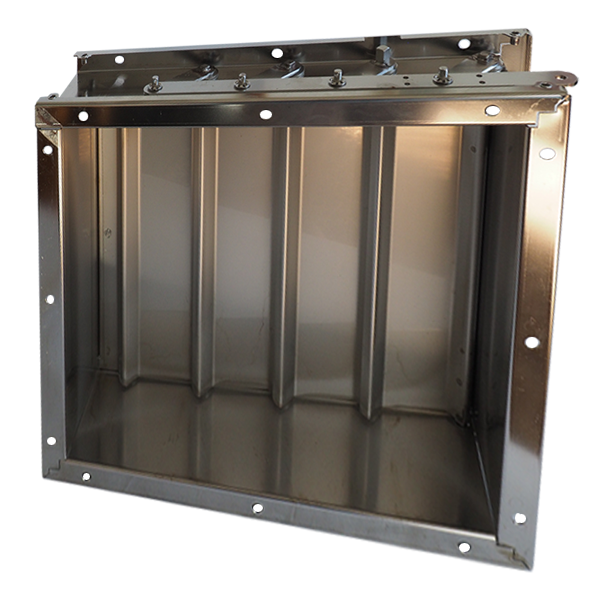

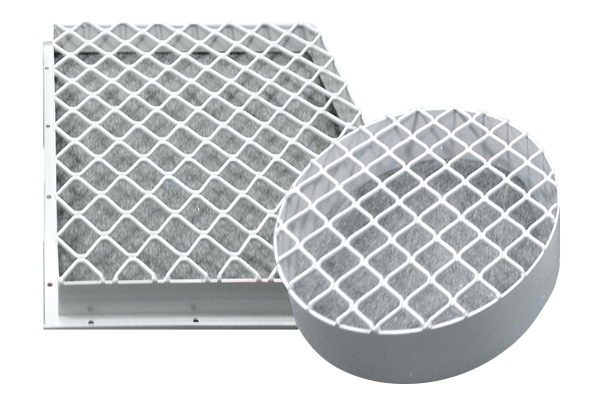

At Marine Air Flow International, we understand that installing SCR systems involves more than just fitting a catalytic converter. Effective operation requires precisely engineered ventilation and airflow management. Our team provides:

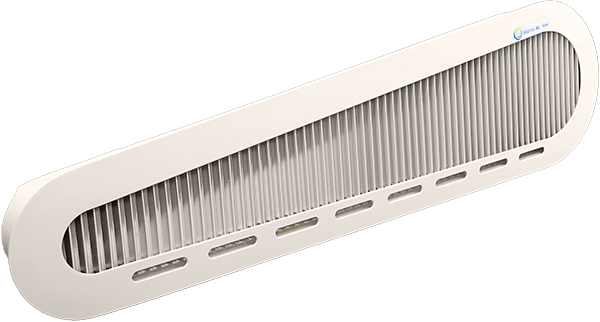

- Custom ventilation solutions to ensure your engine room operates at maximum efficiency, despite SCR systems.

- Lightweight, durable ventilation systems, using sustainable green materials wherever possible. This helps to support your commitment to environmental considerations.

- Integration expertise across a wide range of vessels, including naval ships, patrol boats, commercial ferries, and luxury yachts.

- Compliance-focused designs that align with NSCV/USL codes and international maritime standards.

With over 20 years of experience in marine ventilation, MAFI has become a trusted partner for operators seeking safe, reliable, and regulation-ready systems.

The Future of Marine Emissions Control

As shipping transitions toward alternative fuels such as LNG, methanol, and hybrid propulsion, after-treatment solutions like SCR will continue to play a critical role. MAFI is committed to supporting this transition by delivering future-focused ventilation systems that complement the latest emission control technologies.

Final Thoughts

Marine Selective Catalytic Reduction systems are essential for meeting today’s strict emission standards and building a sustainable future for shipping. With the right design, integration, and ventilation support, SCR technology not only keeps vessels compliant but also demonstrates a strong commitment to environmental responsibility.

At Marine Air Flow International, we help shipbuilders and operators get the most from their SCR installations, delivering systems that are efficient, reliable, and built for the future of marine engineering.