Delta T in Engine Cooling: Optimizing Vessel Efficiency

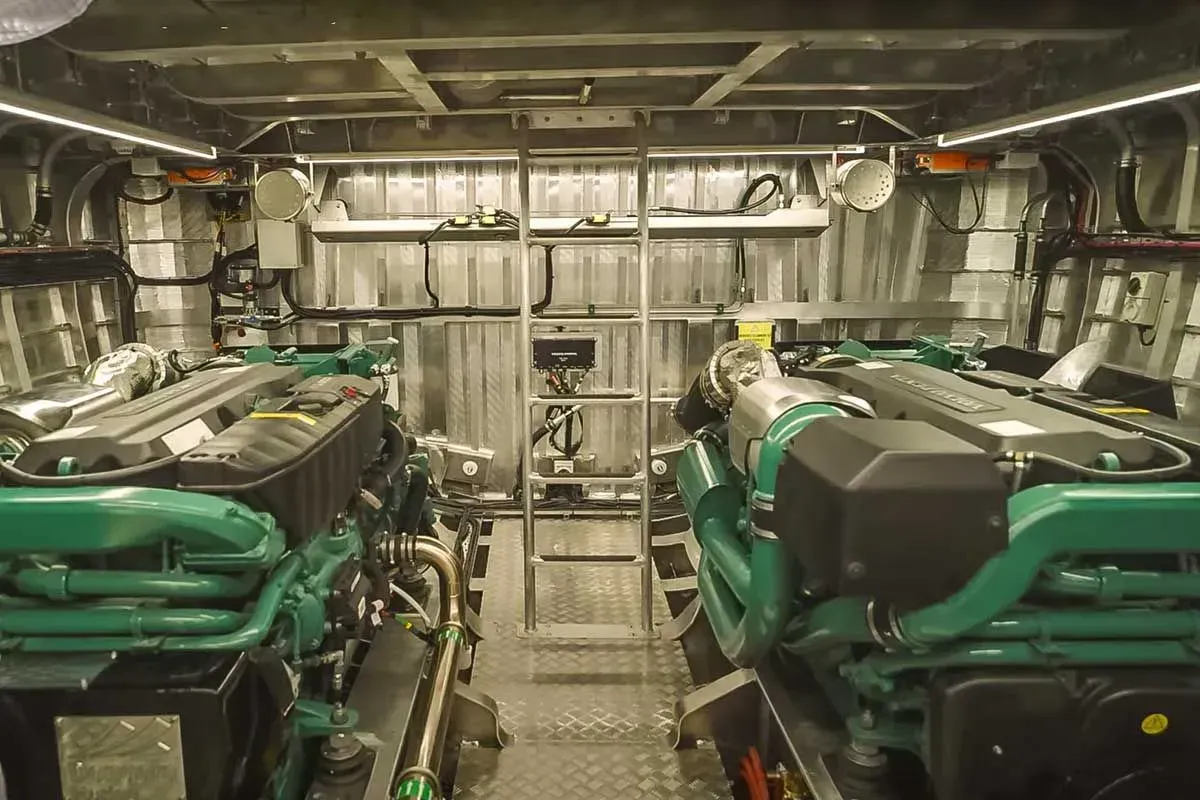

Understanding the Principle of Delta T and Its Role in Cooling a Boat's Engine Room

What is Delta T?

Delta T, simply put, represents a change in temperature (ΔT). It is a little more complex than that, however basically it is a fundamental concept in thermodynamics that plays a significant role in various cooling and heating processes.

In the context of a boat’s engine room, understanding and managing Delta T can mean the difference between efficient operation and overheating disasters.

Why Delta T Matters in Engine Room Cooling

Boat engine rooms are subject to enormous amounts of heat generation. If not managed properly, this heat can lead to engine failure or even catastrophic damage. Delta T helps us measure and control the temperature differential between the hot engine room and the cooler outside ambient air brought in for ventilation.

Assessing Delta T in Boat Engine Rooms

1. The Basics of Heat Transfer

Heat produced by machinery will increase the engine room air temperature. By exchanging the heated air with cooler outside ambient air, we are able to regulate the temperature. Delta T is a measure of how efficiently this regulation takes place.

2. Measuring Delta T

- Outside Ambient Temperature: The temperature of the air entering the engine room.

- Output Temperature: The temperature of the air leaving the engine room.

- Delta T Formula: ΔT = Output Temperature - Input Temperature

A higher Delta T indicates poor ventilation, while a lower Delta T signals effective cooling.

Managing Delta T in Boat Engine Rooms

Ventilation Systems

Efficient ventilation systems help maintain optimal operating conditions by minimizing Delta T. These systems bring fresh air into the engine room while expelling hot air.

Key Components of a Delta T-Based Cooling System

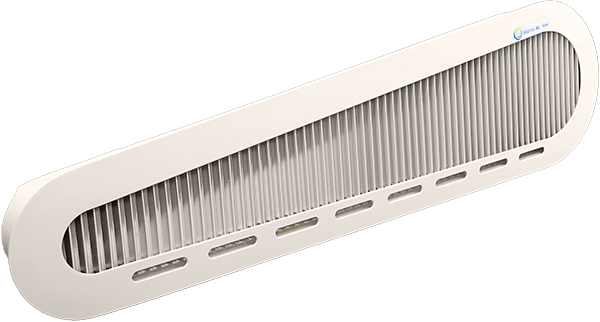

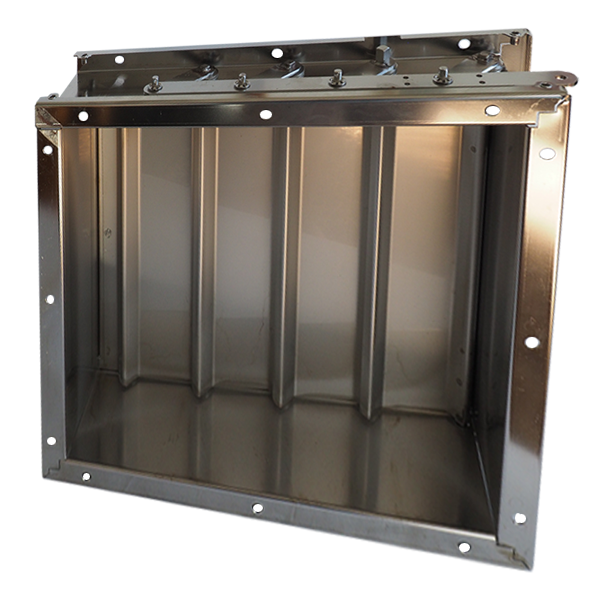

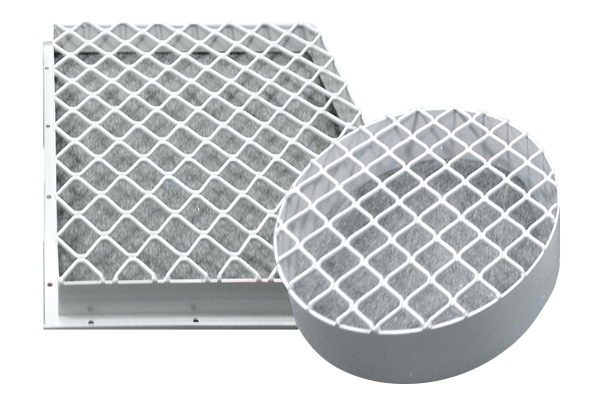

1. Intake Grilles

- Allow fresh air to enter the engine room.

- Removes salt laden air and spray

- Can be single stage or double stage for heavier operating conditions

- Designed to suit your vessel use and application.

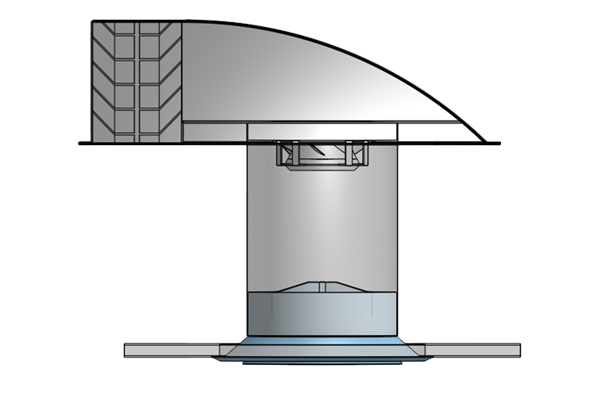

2. Ventilation Fans

- Increase air flow into the space

- Expel hot air efficiently.

- Can direct air flow to important areas

- Powered by controlled automation systems.

3. Temperature Sensors

- Strategically placed to monitor air temperatures.

- Provide real-time data for correct assessment.

4. Control Panels

- Central hub for adjusting fan speeds, monitoring temperatures, and ensuring system efficiency.

The Role of Automation in Engine Room Management

Automation has revolutionized engine room management in modern boats. Advanced systems:

- Continuously monitor temperatures.

- Automatically adjust airflow and cooling mechanisms.

- Alert operators to potential issues before they escalate.

Benefits of Managing Delta T Effectively

- Improved Engine Performance: Consistent cooling maintains optimal operating temperatures.

- Reduced Maintenance Costs: Prevents overheating-related damage.

- Increased Safety: Minimizes risks of engine room fires.

- Energy Efficiency: Reduces power consumption by optimizing ventilation and cooling systems.

Tips for Optimizing Delta T in Your Boat’s Engine Room

1. Regular Maintenance

- Clean intake grilles regularly.

- Inspect and replace worn-out fans and sensors.

2. Invest in Quality Equipment

- Choose high-efficiency fans and mist eliminator grilles.

- Opt for automated control systems for real-time Delta T management.

3. Monitor Temperature Trends

- Keep a log of temperature readings.

- Address anomalies promptly to prevent larger issues.

4. Optimize Airflow

- Avoid obstructions near vents and ducts.

- Ensure fans are positioned for maximum circulation.

Real-Life Example: Managing Delta T on a Mega Yacht

Imagine a luxury yacht cruising through tropical waters. The engine room is a hive of activity, with engines running at full capacity. Here’s how Delta T principles come into play:

- Initial Readings: Air entering at 30°C and exiting at 50°C (Delta T = 20°C).

- Adjustments: Increasing fan speed reduces the exiting air temperature to 40°C (Delta T = 10°C).

- Result: Improved engine efficiency and a safer operating environment with an extended fuel range.

Challenges in Managing Delta T

1. Harsh Marine Environments

- Salt, humidity, and debris can damage ventilation systems.

2. Space Constraints

- Limited room for large fans or ductwork.

3. Power Consumption

- Balancing cooling efficiency with energy use.

Future Trends in Delta T Technology

- Smart Sensors: AI-driven systems for predictive maintenance.

- Eco-Friendly Solutions: Solar-powered ventilation fans.

- Advanced Materials: Corrosion-resistant components for longer lifespan.

Conclusion: Delta T For Engine Rooms

The principle of Delta T is a cornerstone of effective engine room cooling on boats. By understanding and managing engine room temperatures, boat owners can ensure optimal performance, safety, and efficiency. Investing in quality equipment, regular maintenance, and automated systems will help you stay ahead of potential issues and enjoy smooth sailing.

Delta T FAQs

What is Delta T in simple terms?

Delta T is the change in temperature due to added heat, often used to measure cooling efficiency.

How does Delta T affect engine room cooling?

A lower Delta T indicates efficient cooling, while a higher Delta T signals potential ventilation issues.

Can I measure Delta T myself?

Yes, with the help of temperature sensors placed at air intake and exhaust points.

What equipment is essential for managing Delta T?

Intake grilles, supply fans, temperature sensors, and control panels are key components.

Are automated systems worth the investment?

Absolutely! They ensure consistent monitoring and adjustments, improving efficiency and safety.