Marine Air Flow 20 Years On!

Marine Air Flow is 20!

20 Years ago Marine Air Flow started in a farm shed in East Trinity. We had finally gotten really sick of the horrific hours that a marine maintenance business took and sold up. While Brad wanted to immediately immerse himself in something else, I insisted that he take a year off. And he did.

He spent a year fishing with his mate Rod, using his backhoe on the property we had (30 acres at East Trinity) and we also took a few trips overseas. When the year was close to ending, he started to put into place the plan for creating Marine Air Flow.

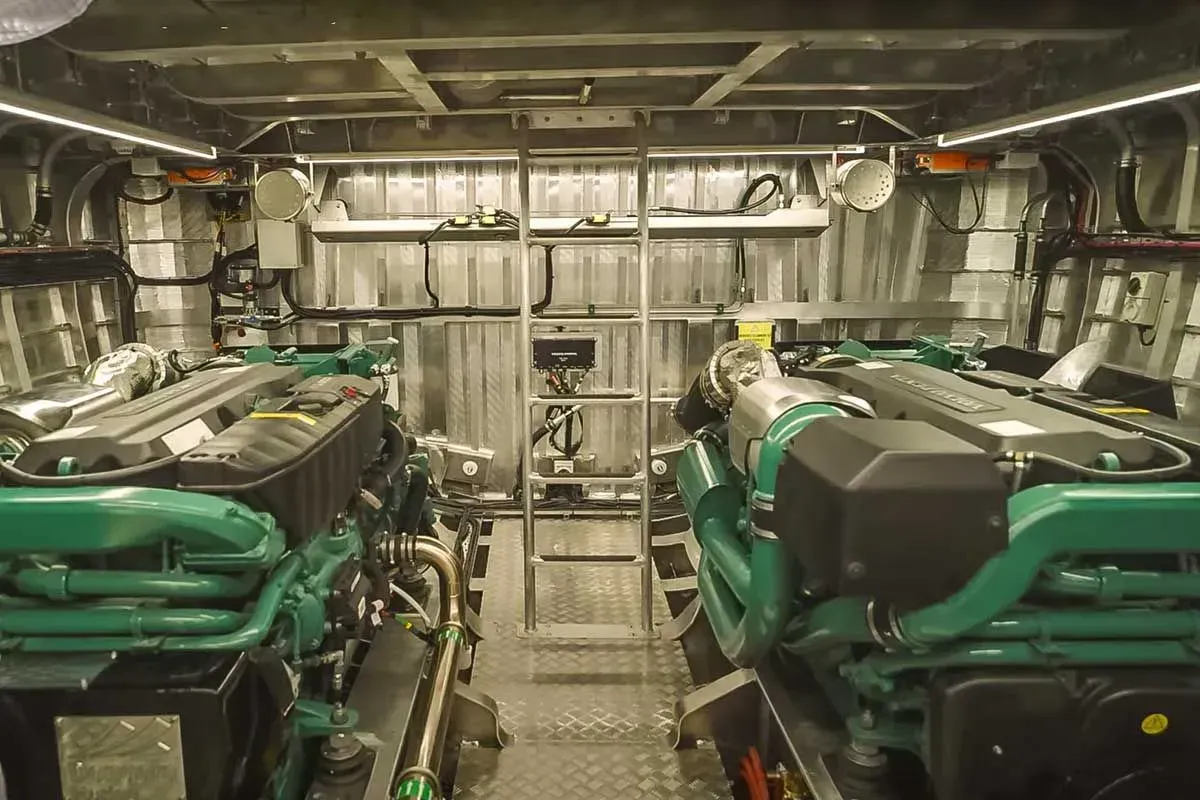

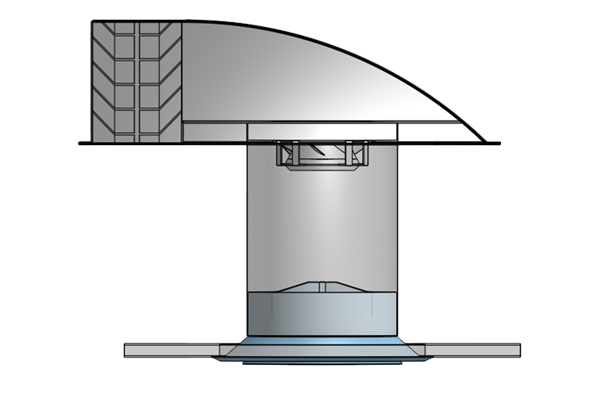

During our time with Profab, our prior business, engine room ventilation was something we just couldn't get. It was available offshore but seemed to be either one of two things: a less than great product, or constructed for military applications where the business wasn't interested in supplying to recreational vessels.

We had dabbled in creating a few "vents" as they were then called but the lack of a dedicated system stuck with Brad and when he was ready, that was what he decided to focus on.

It has been far from plain sailing and a MASSIVE amount of work, dedication and pure commitment from Brad has meant that today Marine Air Flow is a leader in its field. Not just in Australia either, we do more than 40% of our turnover as export today.

Things Have Gone Wrong

Very early on, Brad was bringing a new drill press home from Cairns city and avoiding a cane truck, it fell off the back of the trailer. That was devastating at the time. It was money we didn't have to spend again and despite insurance covering it, we had to wait 2 months for another to arrive. It seems so trivial now, but at the time it meant that I spent hours in the shed with Brad every month manually drilling fixing holes.

At one point after moving the whole thing to the Gold Coast, a staff member let us down very badly and Brad missed a holiday to Fiji to cover for it. That one sucked.

I got a steel sliver off a wire brush in my finger while I was doing some kind of finishing, which got horribly infected and put me off my own work for 3 weeks. Turns out you can't type with a finger bandaged to be the size of a sausage! That damn metal bit is there to this day!

Brad jumped off the trailer at one point and ruptured the ACL in his knee. This was when we found out that directors aren't covered under workers comp. I had to use the insurance from a motorbike trip we were supposed to be doing in Africa to cover Brad's knee reconstruction. To this day, we've never done that trip.

About 3 years into Marine Air Flow, Brad went on a sales trip to WA which left us with $30 in our business account. I can't begin to explain just how scary that was!

There Has Been Some Amazing Achievements Along The Way

I remember the day that Riviera committed to us being their one and only supplier of ventilation equipment for all their new boats. It was so very exciting for us and we thank them for their amazing commitment to us over the last decade.

We now regularly do work for the Australian Government, local and international boat builders, foreign military projects, and even roll-on-roll-off ferries.

Some amazing outcomes:

- Thian one of our mature age apprentices won Apprentice Of The Year, and Jacob has just been nominated this year for the second time.

- We are now a team of 24 with team members from Myanmar, Thailand, Brazil, Spain, France & Argentina

- Blake one of our original apprentices has now been with us 17 years. He is married with 2 children the oldest of which is 10!

- Mark has been with us for around 14 years from memory, is also married and has a son now.

- Joh our accounts person has been with us the entire way and we are so grateful to her for her hard work and putting up with Brad's receipt collecting. Her children that weren't even born when we started are almost fully formed humans now!

- Our factory is now 1200 square meters and we could do with a little more space if I'm honest.

- We won the Small Business Exporter of the Year award last year which was pretty epic, and then

- We also won the AIMEX Exporter of the year this year in 2025.

Equipment has evolved from the manual drilling to CNC machines, laser cutters, automatic benders and we are currently investigating robotic welders.

We have evolved from Brad writing hand written invoices (remember those little carbon copy invoice pads?) to running almost our entire operation from the Zoho suite of software tools.

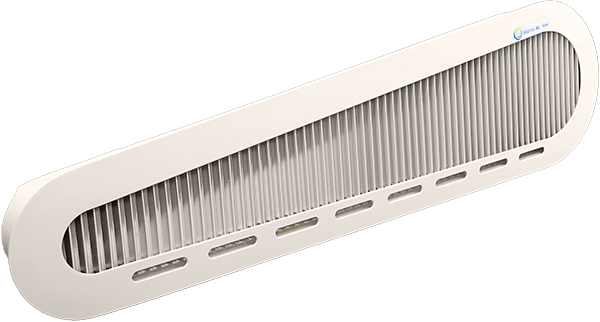

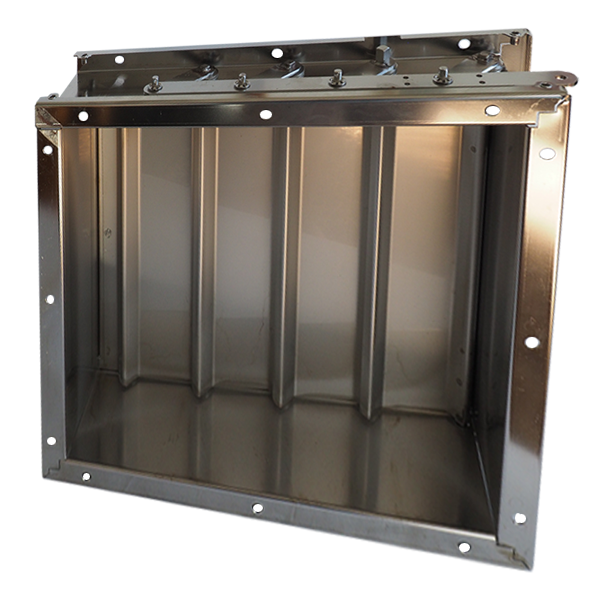

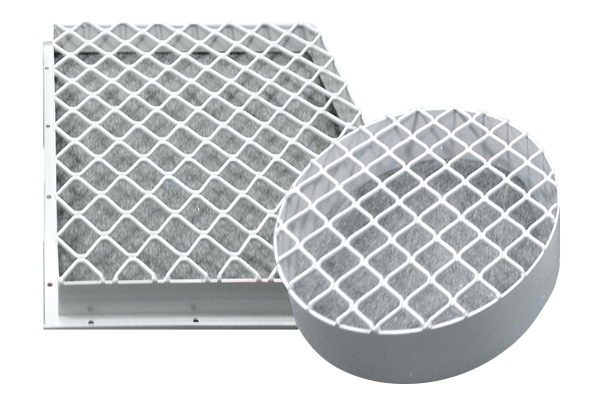

We now have over 30 products in our line up but our Air Intake Grilles still top the sales chart every quarter.

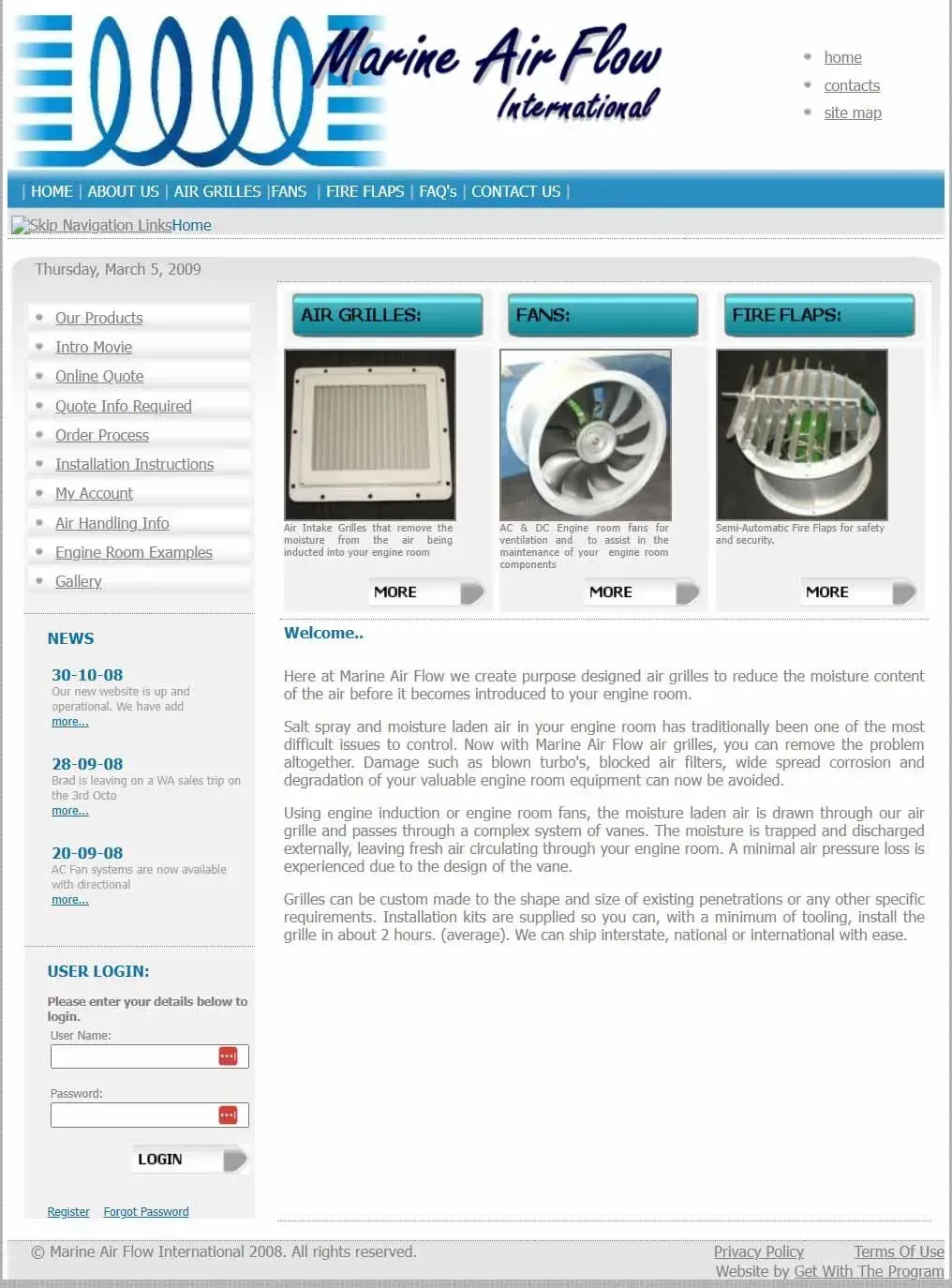

Our Website Has Been and Still Is One Of Our Biggest Assets

Yes, sure this is because I am a web developer by trade and we embraced the technology as a way to get our name and products out there. However, there have been multiple evolutions over the 20 years and will be more to come.

Our Team Is Our Biggest Asset

We are always extremely grateful to our amazing team of very hard workers. Marine Air Flow has:

- a production team,

- a design team,

- a estimating and quoting team,

- a technical and development team,

- an assembly and dispatch team and

team leaders for all of those.

Some of our team have mechanical engineering degrees, there's an MBA in there, and even a Database Administration degree however you don't need a formal qualification to work with us. Some of our best workers are fully self taught and are just as valuable to us as anyone else.

Some Numbers:

- 4 - we work 4 days a week Monday to Thursday

- 32 - monitors in our office

- 27,000+ - The amount we spend on software per year!!

- 4200+ - Cans of soft drink consumed from the smoko hut fridge per year

- 1,000,000+ - Christmas lights in our electrical wizard Matt's house every year. Get in touch at the end of the year for the address to see it. It's pretty amazing.

- 1 - tonnage per month in spacer we have to use before Brad promised he would buy us a company Maserati! We are getting close....

- 4 - Office dogs we've had. Squirt a 65 kg Great Dane, Miss Monroe a 40 kilo Hungarian Vizler, Prada an American staffy with a very distorted face from her cleft palate & Chloe an English staffy with a serious overbite!

- 382 - The combined age of Guns and Roses band members when we all went to see them for our Christmas party in 2023.

- 10 - The years our local Magpie Neil has been with us for. He has a damaged foot and the boys named him Neil after one of our guys who they said used to squark and carry on. He hangs out around the house and factory and comes in the smoko hut looking for crumbs most days. It will be a sad day when we realise Neil is missing.

- 4000+ projects completed to date

Thank You

Thank you to our amazing team, our incredible clients and everyone who has helped us along the way.

They say it takes a village and in this case its more like a small city.

You all know who you are and we thank you from the bottom of our heart!

Jen