Engine Room Air Dampers (Fire Flaps) Explained

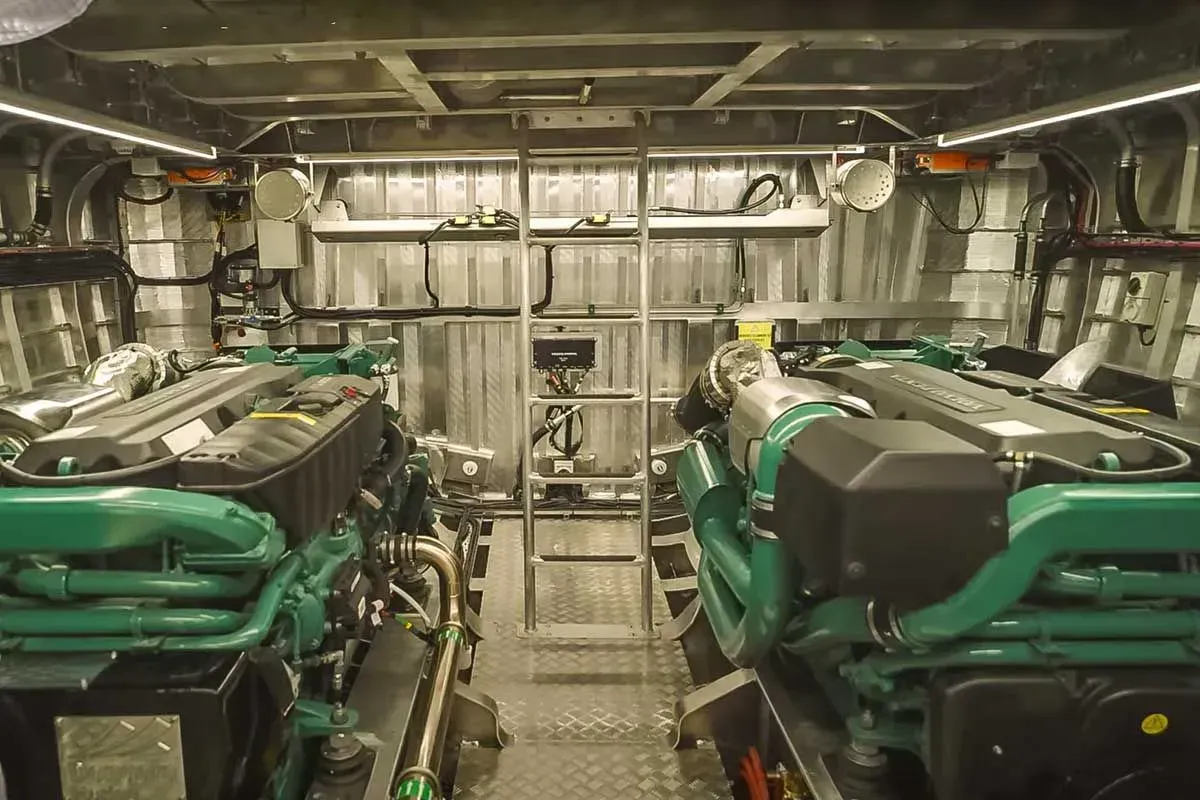

Engine Room Air Dampers And Why Your Boat Needs Them

A fire damper on a boat or ship is a crucial safety component, primarily designed to prevent the spread of fire and smoke through a vessel's ventilation system. While the term "fire flap" is outdated and we now call them Air Dampers, however you refer to them - they are a necessary component in your engine room ventilation system.

Here’s a comprehensive understanding of fire dampers in a maritime context.

What is an Air Damper?

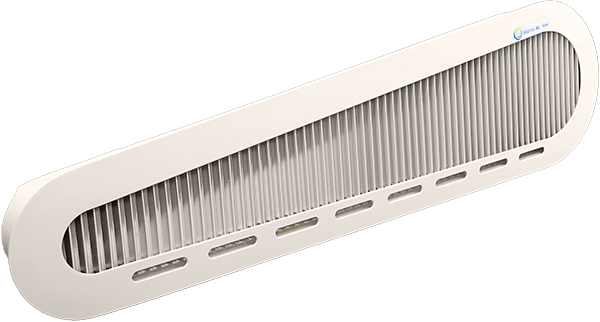

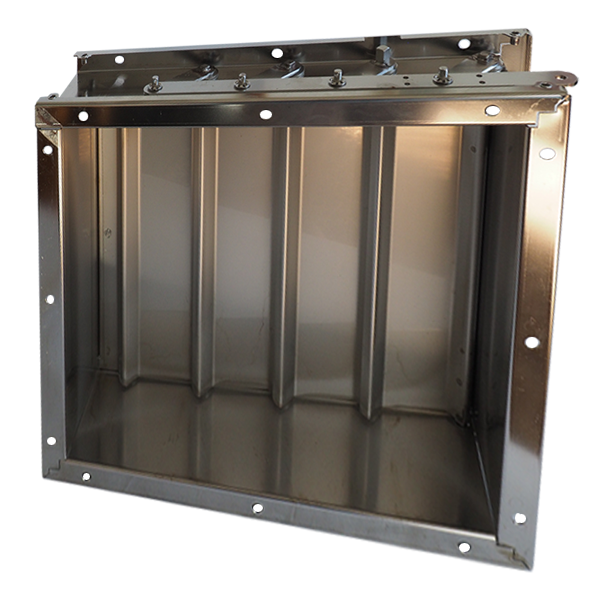

An Air Damper is a device installed as part of a vessel's ventilation system. In its simplest form, it consists of a set of louvers or blades that can close tightly, thereby sealing off the duct and/or air supply.

These blades are held open under normal conditions but are designed to either be manually closed or automatically closed when a certain temperature (indicative of a fire) is reached. They can also be set up to be activated upon receiving a signal from a fire detection system.

Why are Fire Dampers Required on Boats?

- Safety Regulations: Maritime safety regulations worldwide often mandate the use of air dampers in specific areas on ships. These regulations ensure that ships meet a global level of safety and are often essential equipment that must be installed for your vessel to meet survey standards.

- Prevent Spread of Fire: The main purpose of a fire damper is to stop or slow down the spread of fire and smoke through the vessel's ventilation system. Since ships have closed environments, unchecked fire and smoke can quickly become fatal to those on board. By triggering the Air Damper a fire is starved of Oxygen making it more managable for crew or fire fighting systems to extinguish.

- Protecting Equipment and Cargo: By restricting the spread of fire, fire dampers can help protect both the ship's vital equipment and any cargo on board from damage.

Benefits of Air Dampers (Fire Flaps) on Boats

- Lifesaving Measures: In the event of a fire, fire dampers can buy critical time for the crew and passengers, allowing them to evacuate or fight the fire.

- Maintain Structural Integrity: By stopping the spread of fire, dampers can help maintain the structural integrity of the ship, preventing further damage and potential loss.

- Lower Repair Costs: By containing fire damage to a smaller area, the repair costs post-incident can be significantly reduced.

- Insurance Premiums: Having a proper fire prevention and containment system, including air dampers, may reduce insurance premiums for ship owners.

Different Types of Air Dampers

There are various types of fire dampers, including curtain, multi-blade, and combination fire/smoke dampers. The type used often depends on the specific requirements of the ship and its ventilation system.

Some recreational vessels can make use of Aluminium Air Dampers, however most global survey codes require the fire dampers to be stainless steel.

How Air Dampers are Triggered

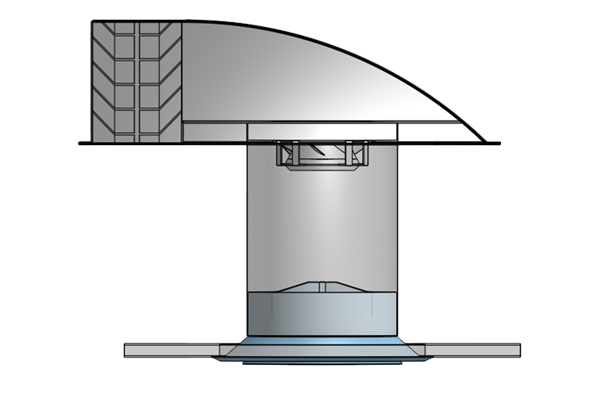

Our Air Dampers come with an optional control cable that extends from the damper to a point outside the engine room. This manual system is simply activated by releasing the pull ring from its holding bracket. Doing so activates the spring-powered damper blade, cutting off the air supply to the engine room.

Additionally, this control has a semi-automatic feature. Should a fire or extreme heat be near the control cable, which is made of synthetic material, it will melt, causing the flap to close automatically. The cable melts at 140 degrees Celsius.

We can also supply an automatic system to trigger the fire flaps. This actuator works via a temperature probe mounted in the air stream inside your engine room. When the probe sense temperatures of 72°C it will shut the damper automatically.

The actuator will also trip if the power supply to the system is turned off. These automatic controllers are a great option for a set and forget situation especially where your vessel might have a rotating crew.

Maintaining your Air Dampers

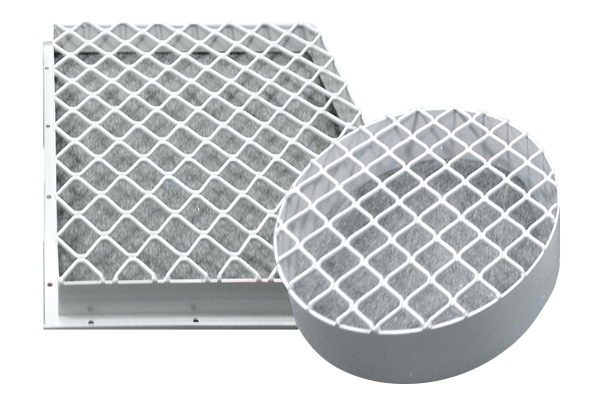

Like all safety equipment, fire dampers must be regularly inspected and maintained to ensure they function properly when needed. This often involves checking the damper's triggering mechanism, its ability to close fully, and ensuring that it isn’t obstructed by debris.

We recommend scheduling an annual inspection for all your fire equipment including any installed dampers and triggering systems.

Instructing Crew On The Use of Air Dampers

Modern ships often integrate fire dampers with their broader fire detection and prevention systems, allowing for automated responses to potential fire threats. Even though this might be the case, you do need to instruct your crew on how and when to reset the dampers and the trigger.

We recommend creating a plaque or poster that is part of your procedures instructing crew on actions to take during a potential or actual fire. Some points to include on this plaque might be:

- sound the alarm and check no one is the engine room

- ensure air dampers have been triggered and are closed

- position vessel safely and shut down engines.

- turn off fuel supply with remote valves.

- turn off ventilation fans with E stops.

- activate fire suppression system

- f in doubt wait for emergency crews.

Most of all, ensure your crew understands not to open the engine room until ALL heat sources have been eliminated.

Understanding the Use Of Air Dampers

In conclusion, fire dampers on boats and ships are an essential part of maritime safety, offering protection to the vessel, its crew, passengers, and cargo. Like all safety measures, their value is often unseen until they're critically needed – and in such moments, they can mean the difference between disaster and recovery.

Get in touch for any help with Air Dampers for your vessel. We would be happy to help. More info and Spec Data sheets can be found on our Air Dampers page.