What Is The Difference Between A Single and Double Stage Intake Grille

Single and Two Stage Marine Intake Grilles Explained

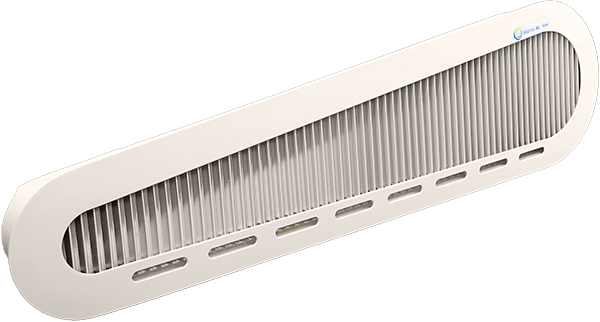

We often get asked the difference between single stage and two stage (or double stage) engine room mist eliminator grilles. This article explains the differences between these grilles and when and where we recommend each one.

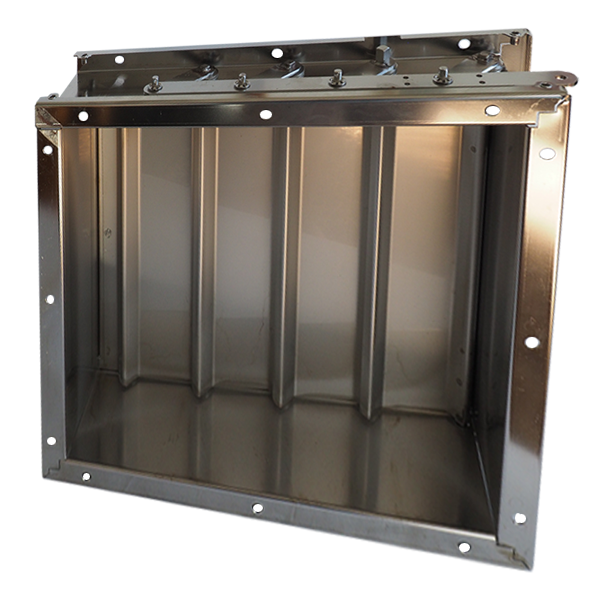

Single Stage Intake Grilles

A single stage mist eliminator is 100mm deep and has a single width core.

The core inside the 100mm section has 3 fingers to trap the salt mist. Those 3 fingers also change the direction of the air each time, creating a small pressure drop. This is often referred to as centrifical spin.

That pressure drop makes the heavy particles, including salt mist drop to the bottom of the mist eliminator then out the drain on the external face of the unit.

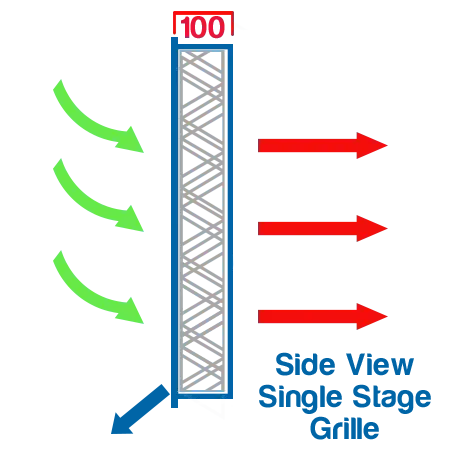

A single stage grille can handle a max average air speed of 6m/sec before they become ineffective. We work on an average of 3.5-4.5 m/sec for safety.

The green arrows signify air in and the red signify air out.

You can see the representation of the core section which makes the air change direction multiple times. This causes the heavy mist to fall out the opening at the bottom of the grille.

Water signified by blue arrow in this example

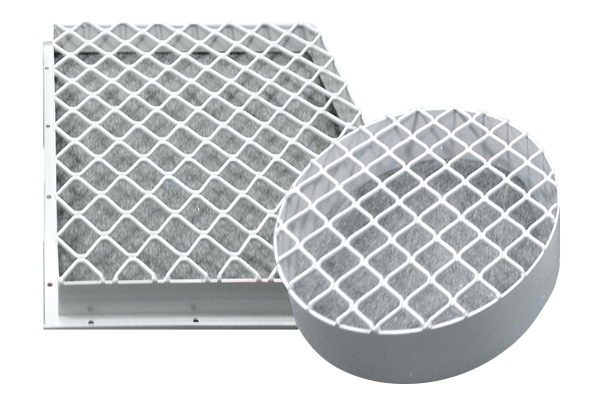

Two Stage (or Double Stage) Intake Grilles

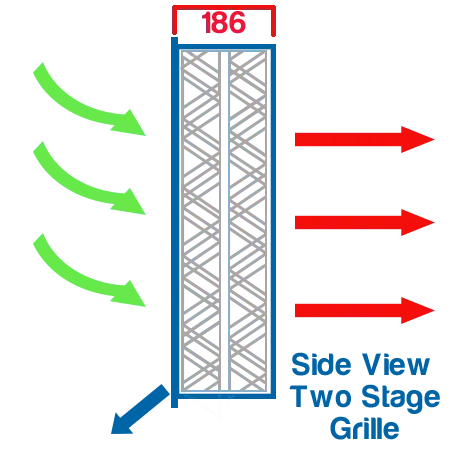

A double stage/2 stage mist eliminator is 186mm deep.

The core inside the 186mm section has 6 fingers to trap the salt mist. Effectively this has "double" the vane section which is why we call them "double" or two stage grilles.

The 6 fingers also change the direction of the air each time, creating a small pressure drop. That pressure drop makes the heavy particles, including salt mist drop to the bottom of the mist eliminator then out the drain (on the external face of the unit).

A double stage grille can handle a max average air speed of 9m/sec before they become ineffective. We work on max 7 m/sec for safety.

The green arrows signify air in and the red signify air out.

You can see the representation of the core section which makes the air change direction multiple times. This causes the heavy mist to fall out the opening at the bottom of the grille. In the double stage (or two stage) example here you can see the vane is effectively "doubled" up.

Water signified by blue arrow in this example

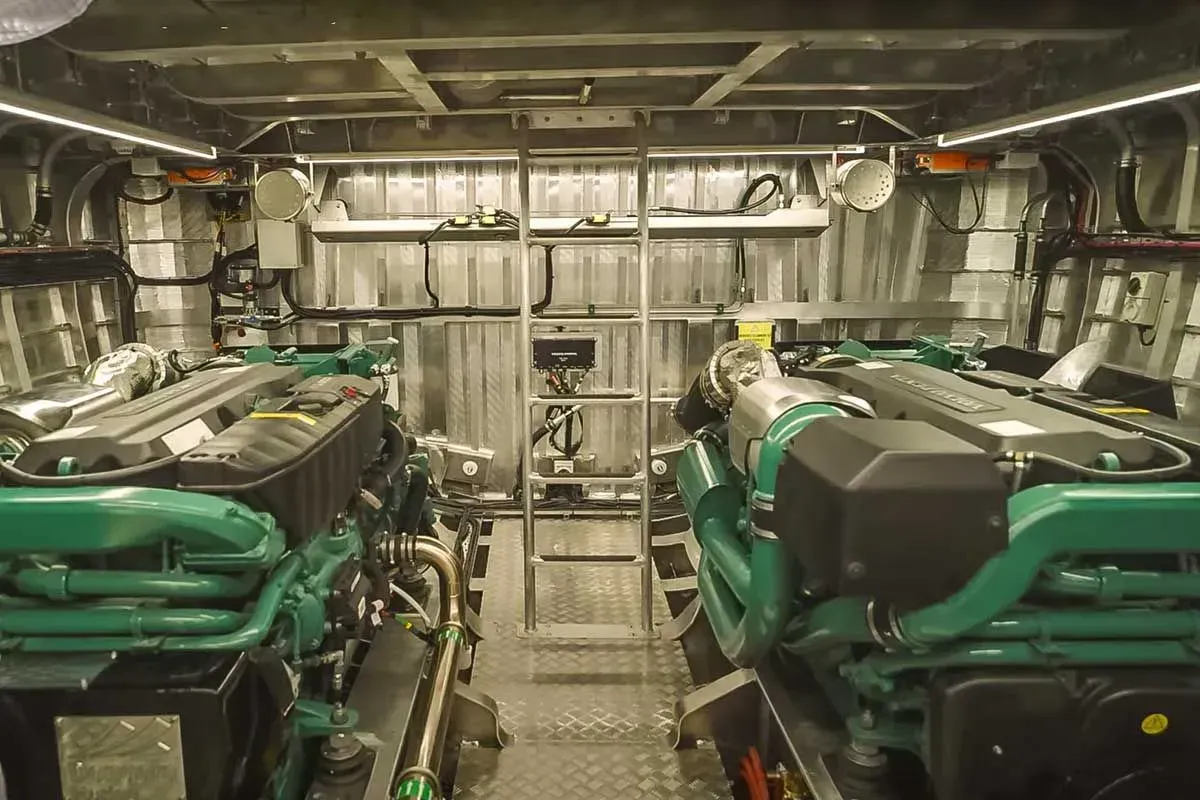

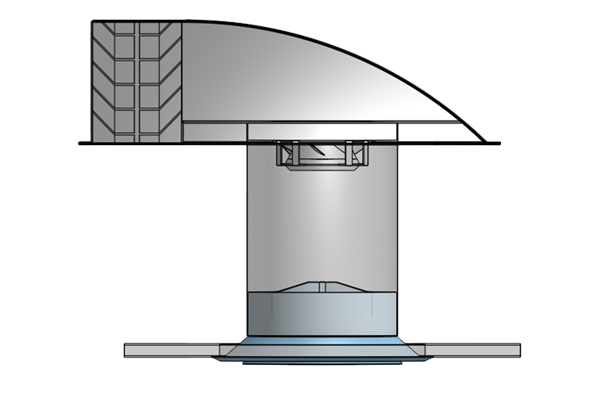

What boats need single stage and which need two stage grilles?

As an example, on a vessel that will operate in heavy sea conditions like a patrol boat, we insist that the air intakes are 2 stage to give the added protection required.

For most recreation vessels used for coastal cruising, single stage is often enough. Should you upgrade to a Mega Yacht that will do ocean crossings, at that point a two stage system would be best. It is dependant on operating conditions primarily as heavier seas and conditions require more mist elimination.

The Air outlets, we are happy to see as single stage as they will have a decent amount of air being pushed out of them, so we are not overly worried about ingress of salt mist and spray due to the airflow direction.

What we do get concerned about and why we recommended having the single stage on the outlets is to protect the vessel while its at rest and also minimise the system pressure.

When the vessel is not operating and the fans are turned off all openings become passive in & out. So while the vessel is at rest there is a probability that the outlets could be fed salt mist from high winds from a storm etc. Hence why we like to see the outlets have a single stage grille on them.

We hope this has helped to explain the use of both single and two stage air intake grilles. Please get in touch for any further assistance required.