The Largest Intake Grilles For Port Of Brisbane

Our Largest Air Intake Grilles For Port Of Brisbane

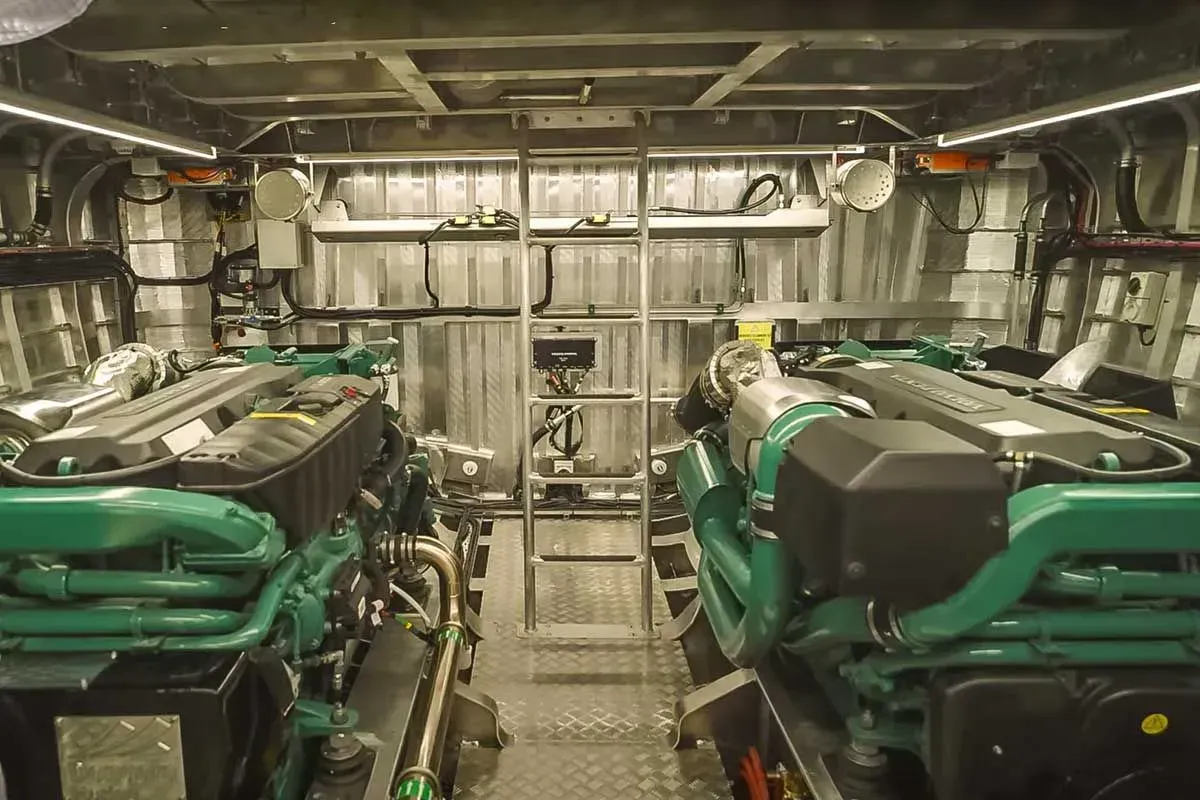

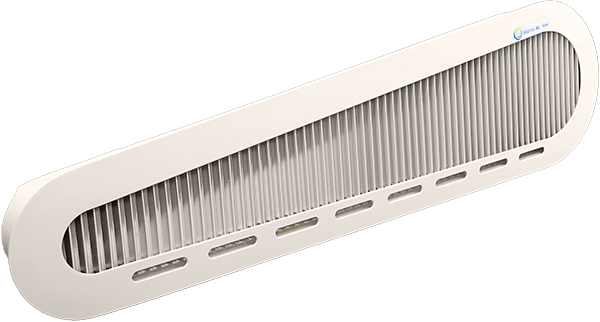

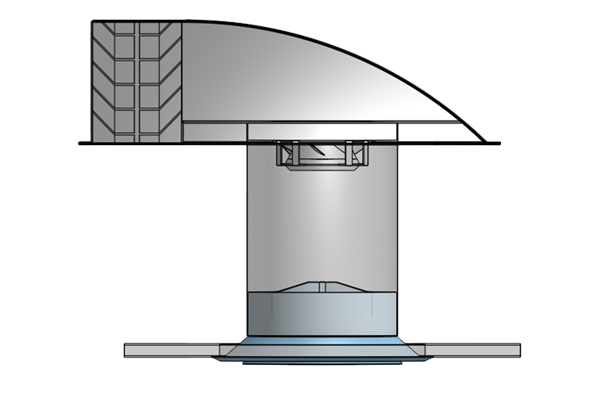

We recently delivered a project to the Port of Brisbane for their trailing suction hopper dredge the "Brisbane" (aptly named). As part of the engine room ventilation system supplied, we manufactured a set of air intake grilles that were over 2100mm on the shortest side. They were in fact almost square which is rare for an intake grille, however the size and shape was designed and calculated to service the air requirements for this massive dredge.

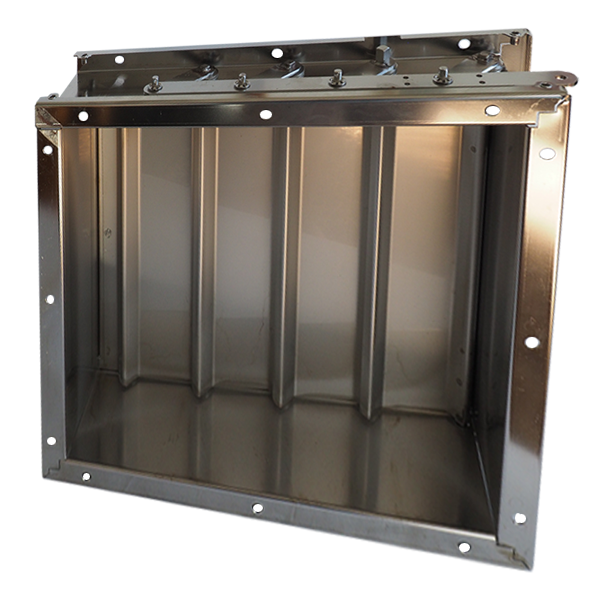

Along with the grilles, additional equipment in the system included Coalescing fabric and frame to suit the grilles, stainless steel air dampers, fans and duct adaptors. While our team manufactured these monster grilles, it was up to Joel our store person to work out how we were actually going to get them to the Port.

While we usually freight all our products, as this project was so close to home we had told the client we would in fact deliver it ourselves. There were discussions of hire vehicles and extra trailers when Brad came up with the idea to remove the carry rack on our own truck which solved the challenge in one foul swoop.

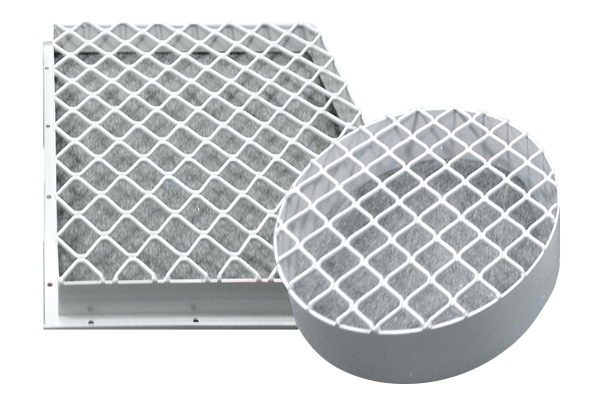

You can see the filter frames complete with coalescing filter fabric and security mesh for the purpose of ensuring the fabric is held in place.

As this grille was so large, we manufactured it in 3 sections. This ensures the vane won't flex and that the grille will work at its most effective level for its lifespan.

Info on the boat and project

Brisbane dredge info:

- 84 m

- 3600 T

- designed and built by NQEA in Cairns 2000

- total engines 4420 Kw (aprox 5750 Hp)

- 2 x single stage intake separator grilles ea aprox 2250 x 2250 - capable of 17 m3/sec of air per grille

A regular challenge for this style of vessel is air borne mist laden with mud that would not only cause significant engine room corrosion, but also create considerable mess and additional maintenance expenses.

The use of removable fabric particulate filters at the Intake Separator Grille face allows that the filters can easily be visually monitored and exchanged with a spare set. The dirty filters are easily hand washed using a low pressure deck hose with either salt or fresh water is fine. The filters can even be replaced while still wet if there are no fresh spares available.

All MAFI grilles are designed and manufactured from high grade marine alloy extrusion & assembled and welded 100% with no dissimilar metals or fixings. This prevents premature corrosion, significantly improving the service life of the product.