NSW Marine Rescue Launches With MAFI Gear

NSW Rescue RIB delivered with MAFI Equipment

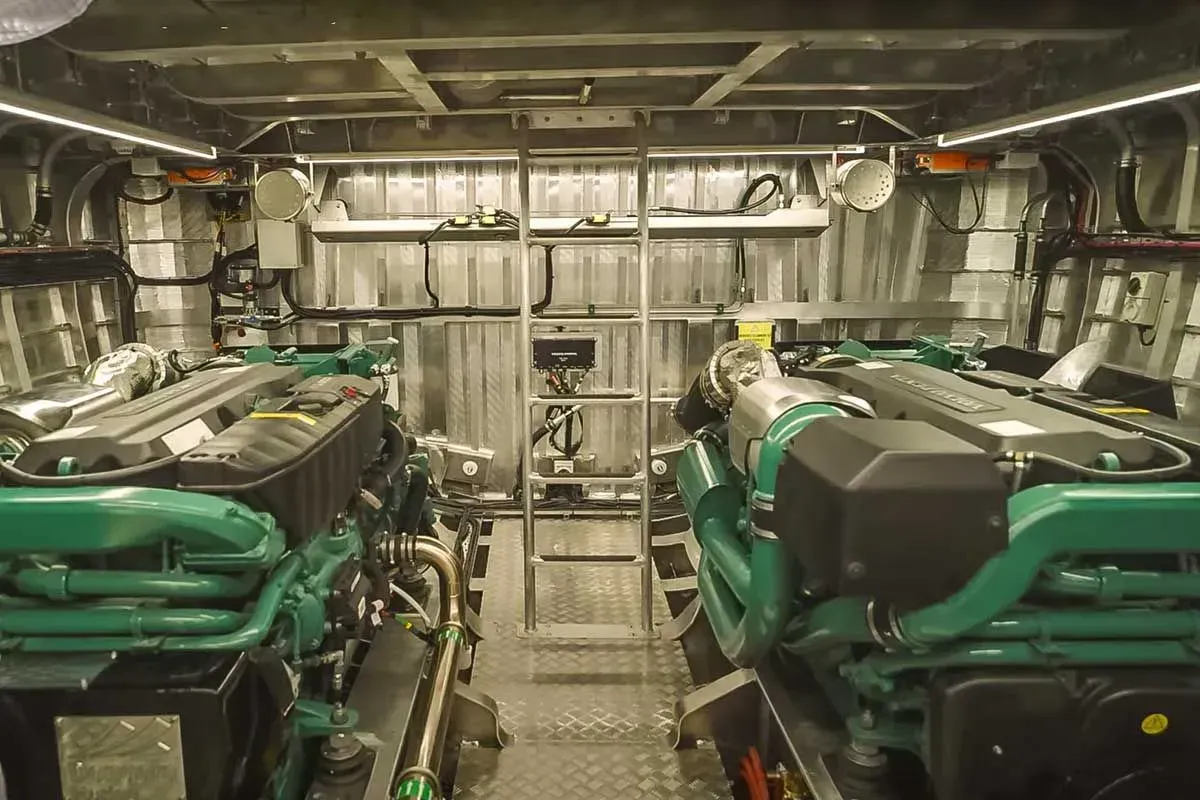

Replacing an existing vessel operating in Jervis Bay, NSW Marine Rescue recently accepted delivery of a new Harwood Marine built RIB complete with Marine Air Flow engine room equipment.

Specifically designed and built for the New South Wales coastal conditions, this new RIB had to be able to not only operate its rescue duties but also to be able to participate in exercises in conjunction with the Creswell naval base.

Marine Air Flow's Ventilation System Details

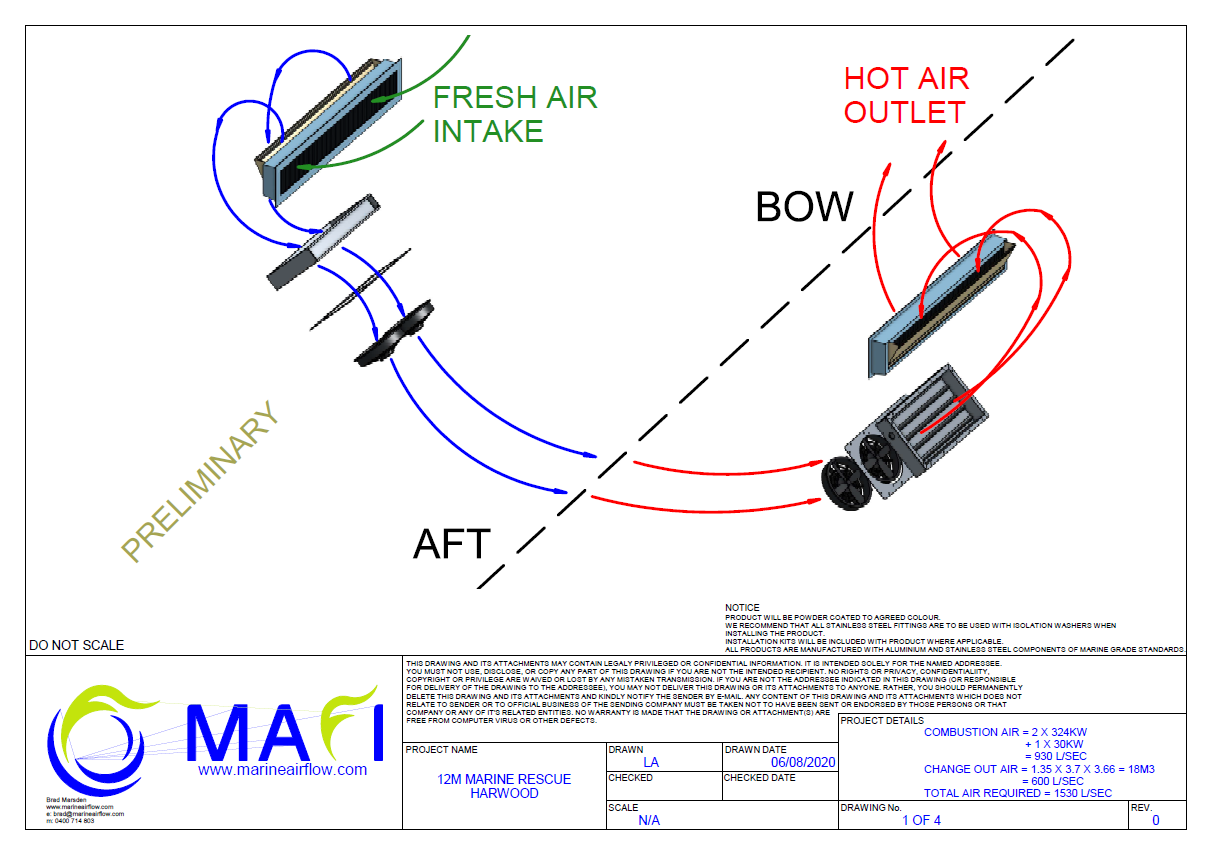

With two Yanmar diesel engines allowing the boat to run at a maximum speed of 30 knots, it was essential that the appropriate engine room cooling system was in place. With the operating conditions in this area being very unpredictable it was also essential to ensure that no salt mist or spray would enter the engine room and degrade valuable equipment.

Vessel Information: 13.6 M RIB for Marine Rescue NSW

The Base main engines are rated at 420 hp each with a total of 840 hp

We also allowed for a single genset at 50 hp operating in the same space. Between these engines we needed to ensure a minimum of 930 l/sec of air to support combustion.

In addition to the combustion air, the engine room volume should be exchanged at 120 times per hour (once every 30 seconds).

The engine room has a volume of approx 18 m³ this needs 600 l/sec for exchange air.

Total air required for this vessel is 1530 l/sec.

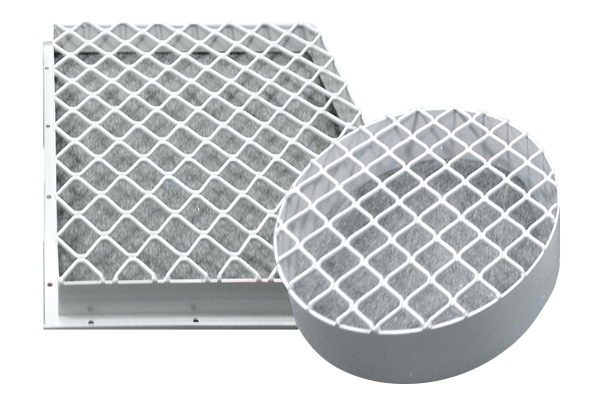

Air intake and Outlet Grilles

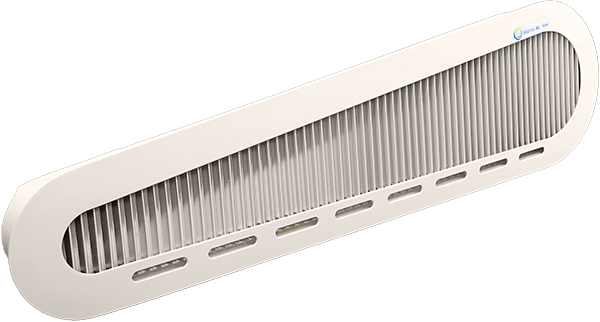

To keep costs down we designed the grilles for this project to be a long single unit rather then 2 shorter units.

These grilles needed to have a minimum sectional area of 0.48m² which meant the physical size is 1600 mm W x 300 mm H. The bullwark depth was 350mm and the grilles were supplied with a full height inbuilt dorade to meet free broad/downing flooding heights.

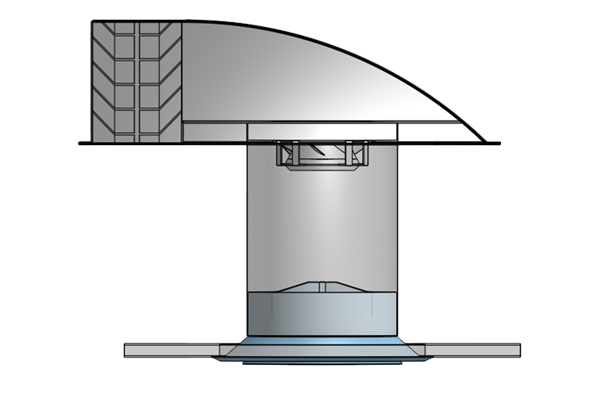

Fans and Air On Demand System

With the amount of air this vessel needed we designed what we call a reversible cross flow system.

We have two 12 inch fans (12 or 24 volt fans) set up as supply (supplying 700 l/sec ea x 2 = 1400 l/sec) and 2 set up as extraction fans.

These fans are also set up with our air on demand system.

Our Air-On-Demand systems are pre-programmed to ensure that your fans only run at the necessary speed which reduces unwanted noise and unnecessary power consumption.

- • At an engine room temperature of 30 degrees celcius the fans will run at idle speed.

- • From 30-40 degrees the fan speed increases relative to the temperature.

- • At 40 degrees celcius the fans will run at 100% until the temperature reduces to 30 degrees at which point they will return to the preset idle speed.

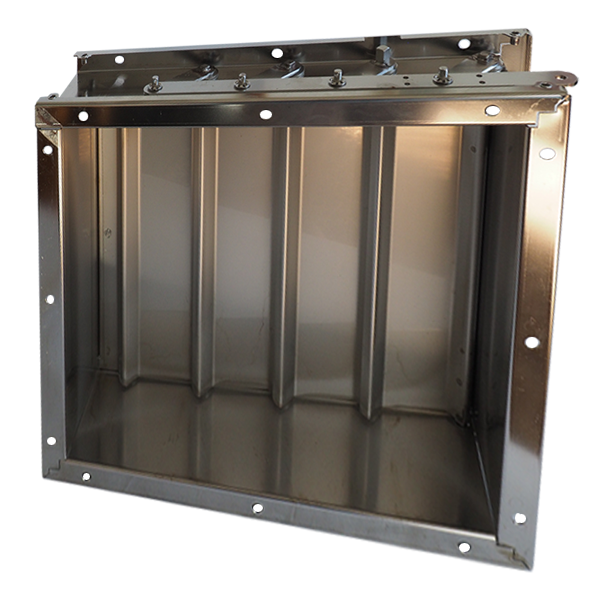

Air Dampers

The dampers have been designed to fit two fans to each unit to save space, with the fan pre mounted to the dampers before they leave the factory for fast installation.

The dampers were provided with a complete manual activation kits including pull handles & operational plaques.

Flow Chart

Grille and Fan Images For This Project