Noise And Our Fans

Fan Noise Calculations

When you look at a subject such as noise levels, there are a number of ways to measure and/or calculate noise levels.

When we offer you a noise level for one of our fans we do this by supplying your the worst case scenario which is referred to as the Sound Power level "CAUSE" or SWL.

Sound power is the acoustical energy emitted by the sound source (in our case fans), and is an absolute value. It is not affected by the environment. Sound power levels are connected to the sound source and are independent of distance.

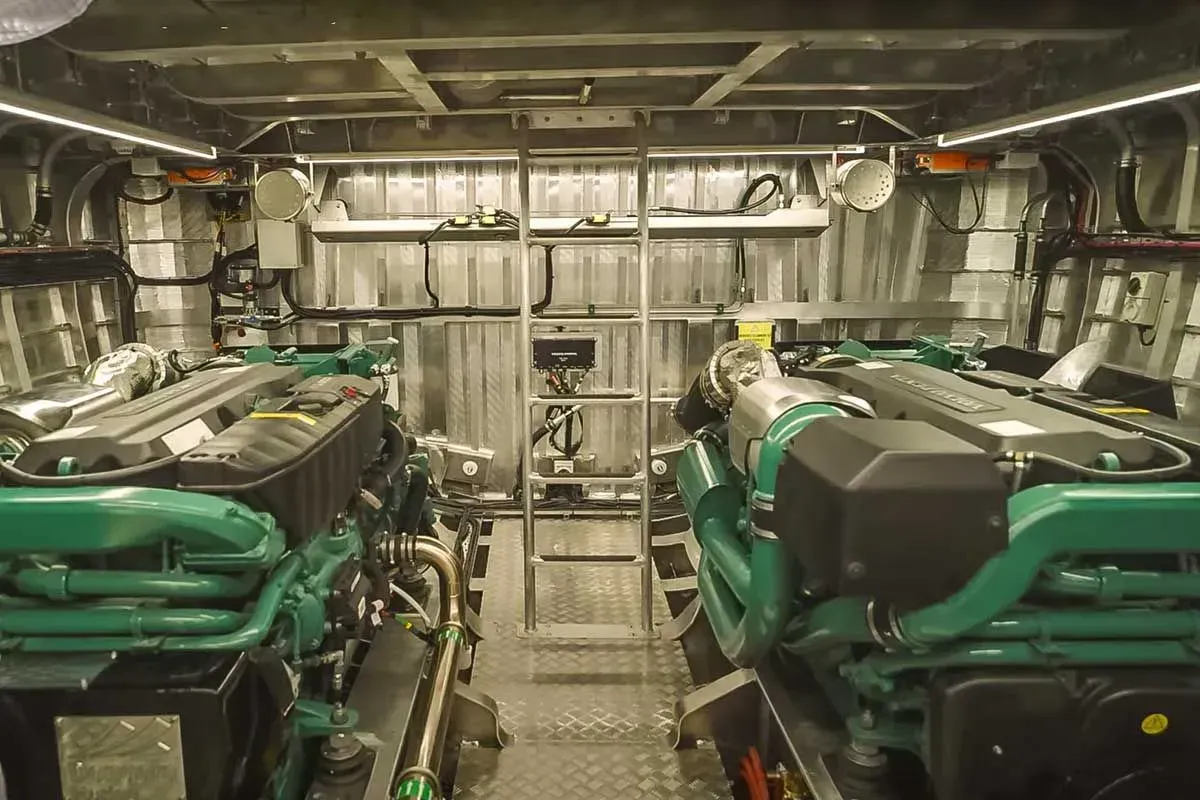

The other common way to show sound levels is called sound pressure often referred to as SPL. This is what a lot of Fan Manufacturer's use as their reference to sound levels. Sound pressure is a pressure disturbance in the air whose intensity is influenced not only by the strength of the source, but also by the surroundings and the distance from the source to the receiver. Obstacles and barriers such as air ducts, air absorption from lagging and insulation, wind as well as other factors are taken into account. So any acoustic paint, insulation, sound attenuaters that you may install on the application to reduce noise will factor into this reading.

Sound pressure is what our ears hear and what sound pressure level meters (SPL meters) measure.

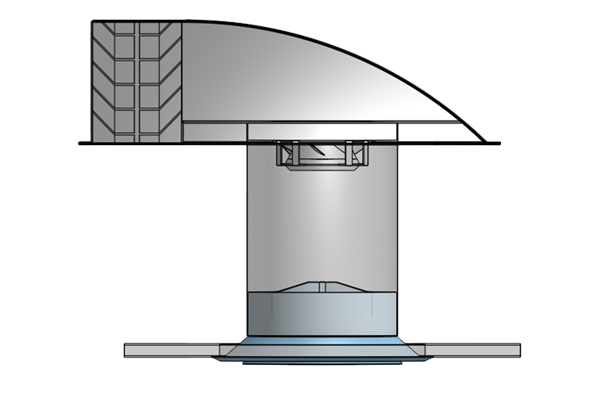

This measurement looks a lot better on the data sheet but can be deceiving as the only way to 100% guarantee this level is to measure the reading in the exact same in environment. We would have to be in the same size area, of the exact same constuction with the exact same components inside the measurement area. In practical terms for an engine room, it would have to be the same size, shape, construction, have the same aluminium duct's, the same intake separator grilles in front of the fan, the same lagging and insulation and the list goes on.

So you can see that the SPL measurement is impossible to state with regards to accuracy. The best way is to provide you with a SWL as that will be accurate no matter the situation.

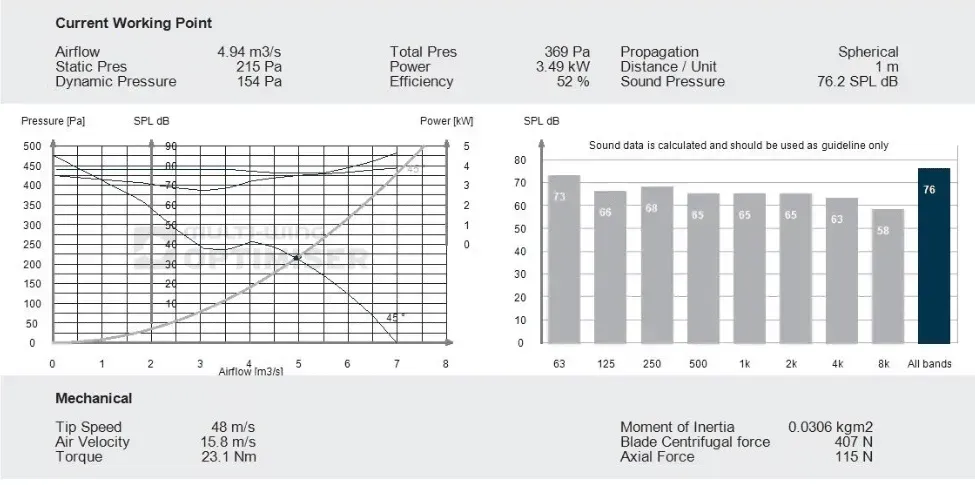

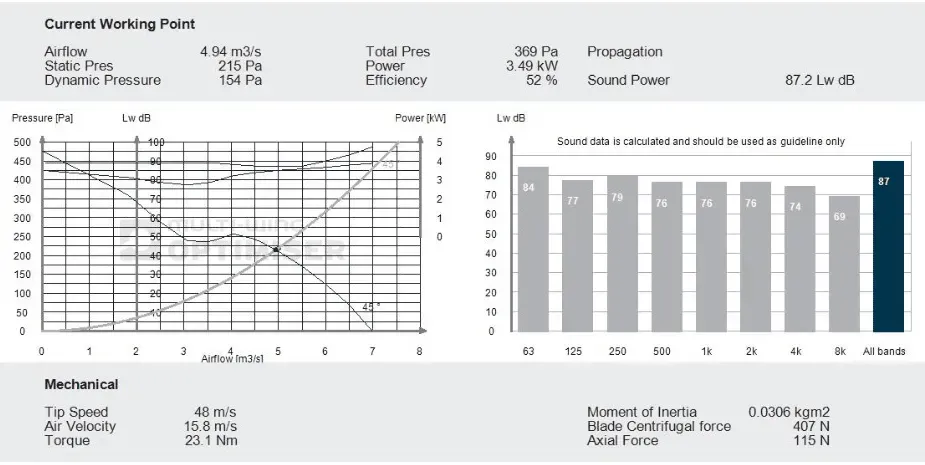

To give you more of an understanding about this we have done two performance graphs of the same impeller/motor assembly.

Option 1 is the Sounds Power (How MAFI will measure sound for you) & Option 2 is the Sound pressure as supplied regularly by manufactures.

You will note that the MAFI sound level is not nearly as low and therefor not so attractive, however it is the most accurate measurement of worst case scenario. Once you install all of your acoustic barriers it a more realistic level of outcome.

We would strongly recommend avoiding the use of sound pressure levels as it will generally lead to disappointment. These levels can be out by 10-15% once installation has occured.

Of course any questions, please get in touch with Brad or Mark who will be able to chat to you about how noise levels relate to your specific application.

Sound Power Graph (As MAFI will supply)

Sound Pressure - As often supplied by manufacturers