How To Lower Your Engine Room Temperature

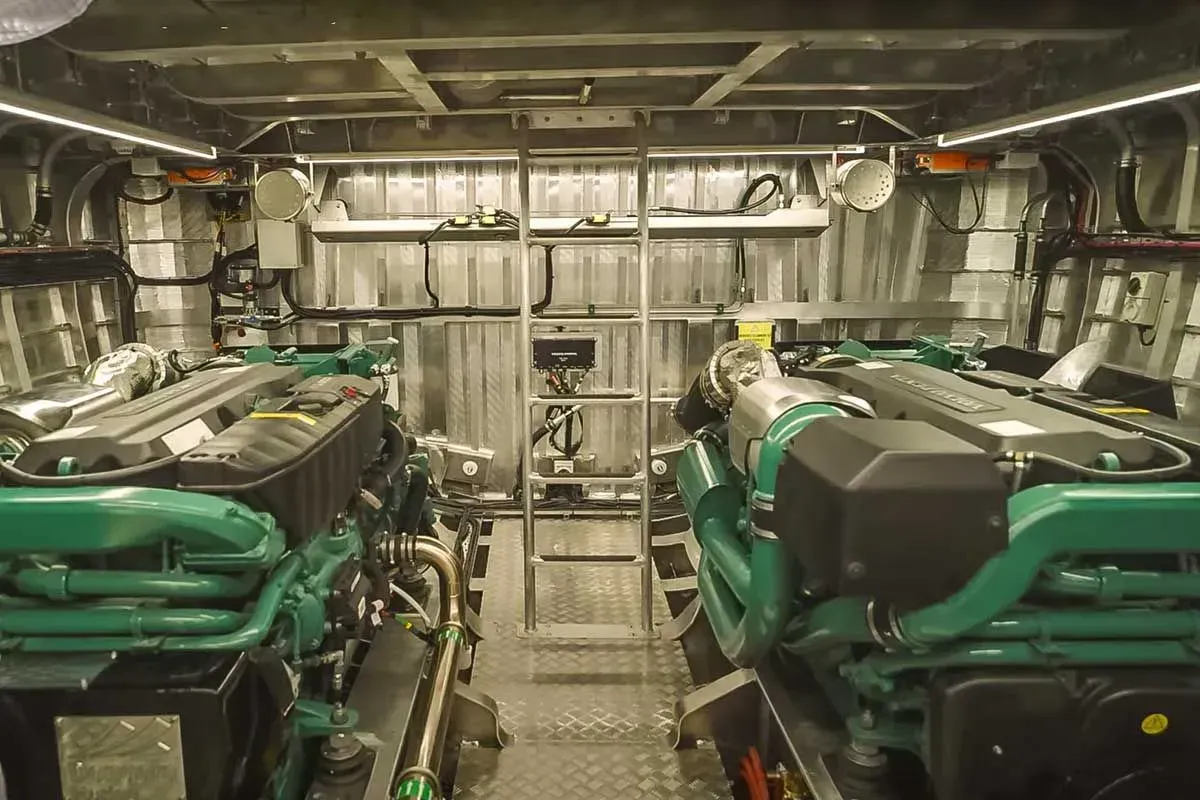

How To Lower The Operating Temperature In Your Engine Room

As a general rule, ideally your engine room operating temperature should try to be maintained at no higher than 10 degrees Celsius above the ambient temperature. So, for example, if its a 32 degree day, in a perfect environment, your engine room temperature should ideally not get above 42 degrees Celsius.

In the real world these parameters can be harder to achieve, however it is possible to take measures that will reduce your engine room temp in a cost effective and easy to manage way.

The cooler air is, the more dense it becomes which by default, offers better operating conditions, which in turn means that you burn less kilograms of fuel per horsepower. Apart from extending the life of your equipment, greater fuel efficiency is a great reason to take steps to bring your engine room temperature into a good operational range.

There are many factors that can increase the operating temp of your engine room such as:

- Dry Exhausts, Turbo's & Manifolds

- Restricted air flow both in and out of the engine room

- Insufficient fan capacity. Size doesn't always equal enough air movement.

- Poor circulation - having fans that either aren't efficient or are poorly located.

- Increasing the engine room equipment (adding extra generators for example)

While some of these factors aren't easily changed, there are some actions you can take that will help to lower the operating temperature and increase your efficiency.

1. Adding Fans:

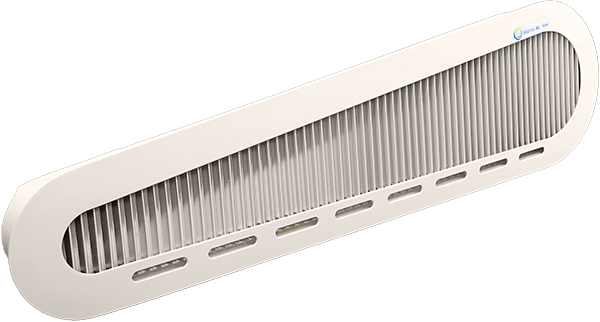

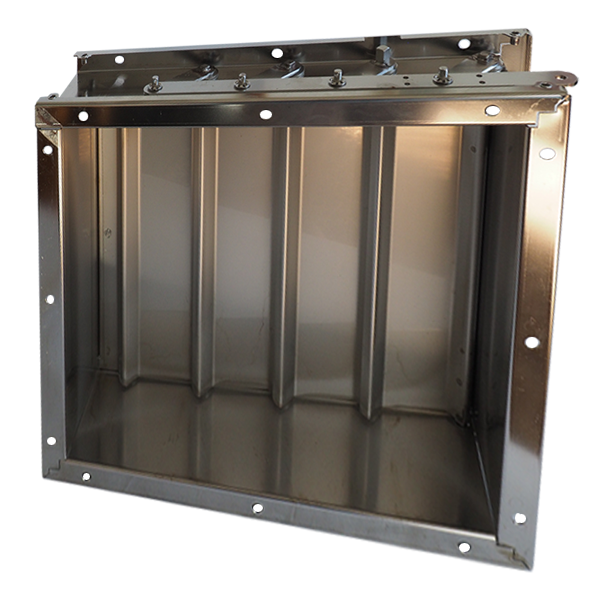

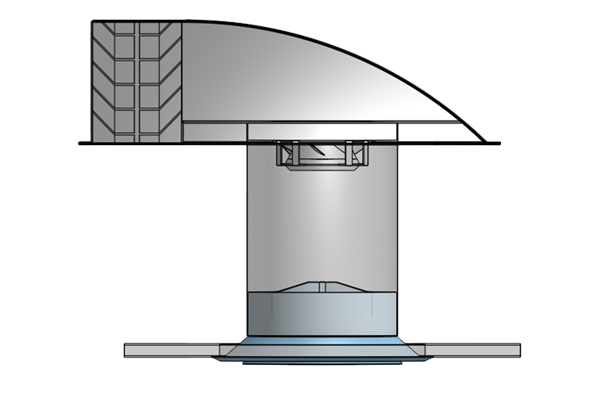

By adding engine room fans, you can increase the air movement and create directional air specifically focused on equipment and/or hot spots.

2. Assessing your air paths:

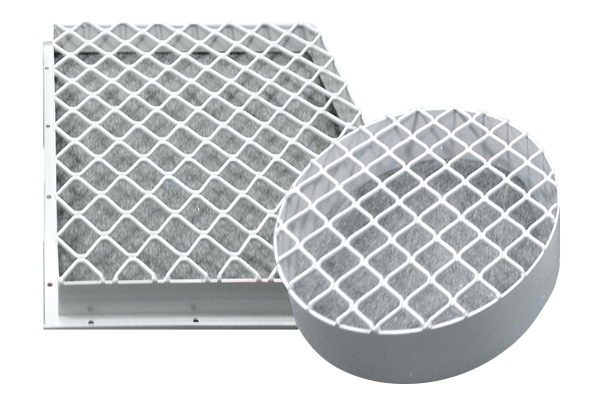

Air is very lazy and just having appropriate sized in and out vents won't necessarily get the best results. You need to ensure your air paths are free and clear which will allow the air to circulate efficiently.

3. Positioning of intake and outlet air vents -

The positioning of your ventilation is critical to its success. Correct placement of both air in and air out grilles will ensure that the air is actually turning over and not just recirculating hot air. The path of the air over your equipment is also crucial in ensuring that the ambient air is in fact changed out regularly. Ideally fresh cool air is supplied low into the ER (engine room) either via ducts or the use of supply air fans discharging the air towards the keel and under the engine sump. Hot air is ideally exited out high and as far opposite the intake as practical.

4. Getting a qualified assessment.

Considering that much of your investment is concentrated in the engine room and frequently monitored via constant data logging by manufacturers for any possible out of warranty issues (like over temperature problems)

It makes sense to get a specialist to visit you on site or assess via a brief interview and calculation. This can usually be achieved over the phone or via email.

We can help to reduce operating costs, improve efficiency and extend the life of your equipment and the stand by availability of your vessel. And also reduce possible out of warranty experiences with your engines manufacturer.

Contact us to arrange a visit.